Client

Our client is a well-established paper production facility located in Argentina. With decades of experience, they have carved out a significant share of the market by consistently delivering quality products. However, as demand increased, so did the need for more efficient material handling solutions to streamline their production processes.

Challenges

Intense Operating Environment: The paper production facility operates in a demanding environment with high temperatures, humidity, and exposure to paper dust and debris.

Frequent Heavy Lifts: The facility requires frequent lifting of heavy rolls of paper, machinery components, and raw materials.

Safety Concerns: Ensuring the safety of workers and minimizing downtime were paramount.

Requirements

The client sought an electric single beam crane that could seamlessly integrate into their existing infrastructure. The primary requirements were:

- A crane capable of handling loads up to 5 tons.

- Enhanced operational speed and precision.

- A robust system that could withstand the demands of continuous operation.

- Compliance with European standards design.

Crane Solution

The client contacted us through our official website. Known for our experience in custom crane solutions, we - DQCRANES are the ideal partner to address the unique challenges faced by the paper production facility.

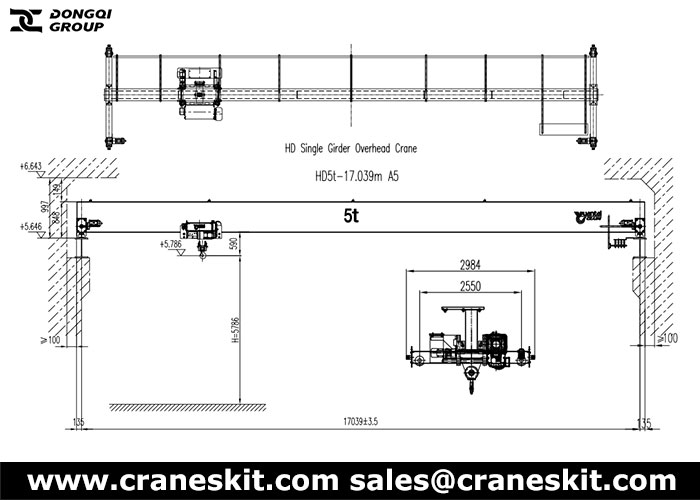

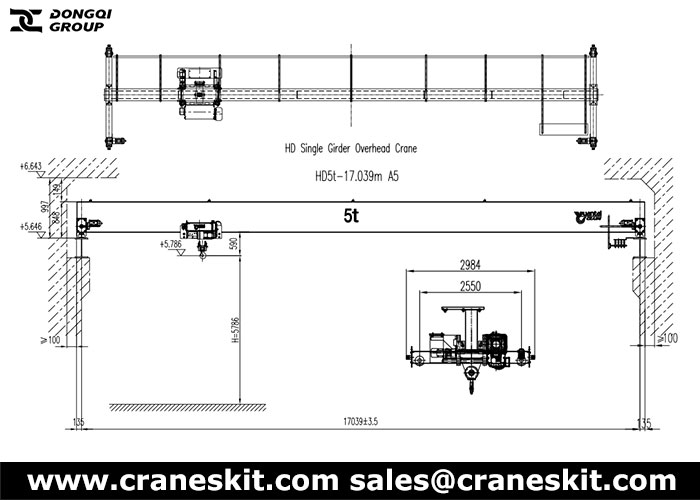

Upon receiving the client's requirements, we initiated a comprehensive assessment of the facility's operational dynamics. Our team of engineers and designers collaborated closely with the client's technical team to develop a bespoke solution: an HD European standard 5 ton

overhead crane.

| Product |

|

HD European standard single girder overhead crane |

| Lifting capacity |

t |

5 |

| Span |

m |

17.039 |

| Lifting height |

m |

5.78 |

| Crane weight |

t |

3.72 |

| Hoist lifting speed |

m/min |

0.8~5.0 |

| Crane traveling speed |

m/min |

2.0~20 |

| Power supply |

/ |

380V, 3Phase, 50Hz |

| Lifting group |

/ |

FEM 2m (A5) |

| Crane group |

/ |

FEM 2m (A5) |

| Control method |

/ |

Pendent control |

| crane rail |

/ |

P15 (Proposing rail) |

| Working site |

/ |

Indoors |

Design Features

Structural Design:

- Main Girder: Typically a welded box-section girder, constructed from high-strength steel.

- end carriages: Robust design with precision-machined wheels and bearings to ensure smooth operation and long service life.

- Hoist Trolley: Designed to handle the specific weight and dimensions of paper rolls, with features like adjustable hook blocks and load-limiting devices.

Electrical System:

Electrical System:

- Control Panel: User-friendly, ergonomic design with clear labeling and easy-to-operate controls.

- Motor Drives: High-efficiency, variable-frequency drives provide precise control of hoist and trolley speeds.

- Electrical Enclosures: IP54-rated enclosures protect electrical components from dust and moisture.

- Emergency Stop: Strategically placed emergency stop buttons for immediate shutdown in case of emergencies.

electric hoist:

electric hoist:

- Lifting Mechanism: NR type single girder hoist, designed with European Standards.

- Hook Block: High-strength, forged hook block with safety latches.

- Wire Rope: High-quality, galvanized wire rope with appropriate diameter and length.

- Limit Switches: To prevent over-hoisting and under-hoisting.

Safety Features:

- Overload Protection: To prevent overloading the crane and its components.

- Anti-Collision Devices: To prevent collisions between cranes or with other objects.

- Emergency Stop: Strategically placed emergency stop buttons for immediate shutdown.

- Braking System: Reliable braking system to ensure safe and controlled movement.

- Regular Inspection and Maintenance: A comprehensive maintenance program to ensure the crane's continued safe operation.

Benefits

- Improved Efficiency: The FEM crane's powerful lifting capacity and smooth operation significantly improved the facility's productivity.

- Enhanced Safety: The advanced safety features minimized the risk of accidents, ensuring a safer working environment for employees.

- Reduced Downtime: The reliable construction and high-quality components reduced the frequency of breakdowns, minimizing downtime.

- Lower Maintenance Costs: The crane's robust design and regular maintenance intervals helped reduce long-term maintenance costs.

- Increased Flexibility: The customizable design allowed the overhead bridge crane to adapt to changing production needs.

- Single Girder Overhead Cranes: Simpler and more cost-effective than Double Girder Cranes. Ideal for lighter loads and shorter spans. Commonly used for tasks like moving paper rolls in storage areas or transporting smaller equipment.

- Double Girder Overhead Cranes: Can handle heavier loads and longer spans compared to single girder cranes. More robust and durable, suitable for demanding applications like lifting large paper rolls or heavy machinery. Often used in the wet end of the paper mill, where heavy equipment and materials are handled.

- Semi-gantry cranes: Combine features of overhead and gantry cranes, with one end supported by a column and the other by a bridge beam. Versatile and can be used in areas with limited headroom or where floor space is at a premium. Commonly used for outdoor storage areas or loading/unloading docks.

- Explosion-Proof Overhead Cranes: Designed to operate in hazardous environments with explosive dust or gases. Incorporate special features like explosion-proof motors, wiring, and control systems to prevent accidents. Used in areas of the paper mill where flammable materials are present, such as the paper machine area.

DQCRANES also offers custom crane systems to meet the specific needs of the paper mill, such as special load capacities, hook heights, or operating environment.

Contact us to learn more!

Why Buy Overhead Cranes from DQCRANES?

Wide Range of Products:

- DQCRANES offers a diverse range of overhead cranes, including single girder cranes, double girder cranes, grab overhead cranes, explosion-proof cranes, winch trolley cranes, European standard overhead cranes, etc. This variety ensures you can find the right crane for your needs.

Customization Options:

- DQCRANES can tailor cranes to your requirements, such as load capacity, span, hook height, and special features. This flexibility allows you to optimize the crane for your specific application.

Quality and Reliability:

- DQCRANES is known for manufacturing high-quality, reliable overhead cranes. Our products are built to withstand demanding industrial environments and provide long-lasting performance.

After-Sales Support:

- DQCRANES offers comprehensive after-sales support, including installation, maintenance, and repair services. This ensures that your crane remains in optimal working condition.

Competitive Pricing:

- DQCRANES strives to offer competitive pricing on our overhead cranes, making them a cost-effective solution for your material handling needs.

If you're looking for a reliable overhead crane solution,

contact DQCRANES today for a free quote and take the first step toward optimizing your material handling processes!