Project Overview

PNC Wood Industry, a prominent wood processing company located in Oregon, USA, specializes in handling a variety of wooden products, including boards and prefabricated parts. To enhance operational efficiency, improve material flow, and ensure worker safety within their facility, PNC Wood Industry sought a comprehensive material handling upgrade. They found DQCRANES to design, manufacture, and install a customized

overhead crane system and supporting steel structures.

Client Needs and Challenges

PNC Wood Industry faced several key challenges:

- Inefficient Material Handling: Existing material handling processes were time-consuming and labor-intensive, leading to production bottlenecks.

- Safety Concerns: Handling large and heavy wooden boards and prefabricated parts posed safety risks to workers.

- Space Optimization: The facility layout required a material handling solution that could maximize space utilization and navigate existing structures.

- Customization Requirements: Standard, off-the-shelf crane solutions could not adequately address the specific needs of PNC Wood Industry's operations. They needed a system tailored to their exact workflow, building dimensions, and load characteristics.

- Reliability and Durability: The electric traveling cranes needed to be highly reliable and durable to withstand the demanding environment of a wood processing facility and ensure continuous operation.

DQCRANES Solution: Custom Overhead Cranes

DQCRANES' engineering team thoroughly assessed PNC Wood Industry's facility, operational requirements, and material handling processes. Based on this assessment, we designed three (3) sets of customized

Double Girder Overhead Cranes.

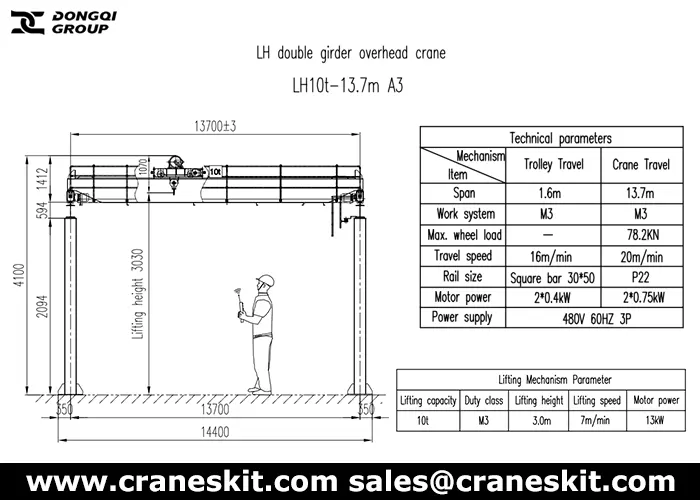

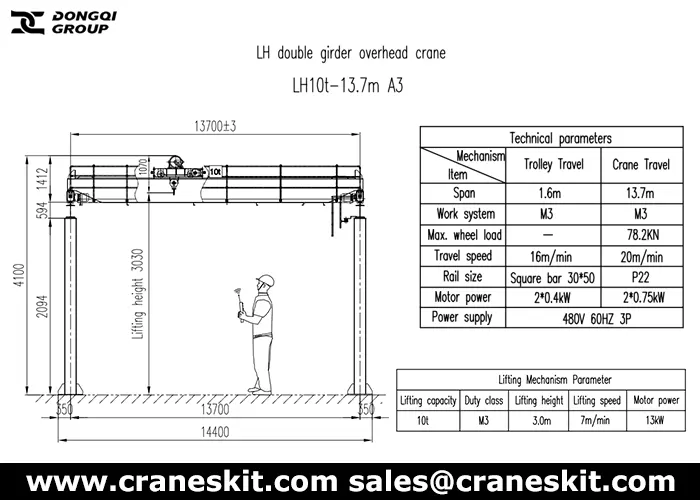

Overhead Crane Specifications:

Overhead Crane Specifications:

- Lifting Capacity: 10 tons per crane

- Span: 13.7 meters

- Trolley travel span: 1.6m

- Lifting Height: 3 meters

- Duty Class: M3

- Lifting Speed: 7m/min

- Crane travel speed: 20m/min

- Trolley travel speed: 16m/min

- Power supply: 480V 60HZ 3P

Design Features:

- Double Girder Configuration: Double Girder Cranes were selected for their superior strength, rigidity, and lifting capacity, making them ideal for handling heavy and bulky wooden materials. This design also provides better hook stability and allows for higher lifting heights.

- Hoist Mechanism: Double girder wire rope hoist with trolleys, optimized for 3-meter lifting height.

- Control System: Dual-mode operation (pendant + wireless remote) for precise speed control (16m/min trolley travel) of crane movements (20m/min), minimizing load swing and improving positioning accuracy.

- Specialized Lifting Attachments: Designed to safely and efficiently handle various types of wooden boards and prefabricated parts. (Specifics would depend on the exact materials, e.g., specialized grabs, slings, or vacuum lifters).

- Anti-Collision Systems: To prevent collisions between the cranes and other structures, enhancing safety.

- Steel Structure Design and Fabrication: DQCRANES also designed and fabricated the supporting steel structures, including runway beams and columns, to ensure structural integrity, stability, and compatibility with the cranes.

Safety Features:

Safety Features:

- Overload Protection: Integrated load limiter to prevent operations beyond 10-ton capacity.

- Limit Switches: Upper/lower hoist limits and end-of-travel stops for trolley and bridge.

- Emergency Systems: Emergency stop buttons on the pendant and remote controls.

- Fail-safe brakes to secure loads during power loss.

- Environmental Protection: IP54-rated enclosures for motors and electrical panels to resist dust and moisture.

- Sealed cable reels to prevent sawdust ingress in wood processing environments.

Steel Structures Design for Overhead Cranes

Effective steel structure design for overhead cranes balances load capacity, environmental resilience, and operational efficiency. By adhering to engineering standards, leveraging high-quality materials, and incorporating industry-specific adaptations (e.g., dust-proofing for wood plants), these structures ensure safe, reliable, and long-lasting performance. Below is a detailed breakdown of design principles, components:

Key Components of Overhead Crane Steel Structuresa) Bridge GirdersDouble Girder vs. Single Girder:

Key Components of Overhead Crane Steel Structuresa) Bridge GirdersDouble Girder vs. Single Girder:

- Double Girder: Preferred for heavy-duty applications (10+ tons), offering greater rigidity, load distribution, and space for auxiliary equipment (e.g., walkways, cable trays).

- Single Girder: Suitable for lighter loads (up to 20 tons in some cases), and cost-effective for shorter spans.

Girder Types:

- Box Girders: Fabricated from welded steel plates (ASTM A36/A572), ideal for heavy loads and long spans.

- I-Beams: Rolled sections (e.g., W-beams) for moderate-duty cranes with spans <15 meters.

Deflection Limits:

- Typically L/1000 to L/800 (span-to-deflection ratio) under full load to ensure stability.

b) Runway Beams

- Function: Support the crane bridge and distribute loads to the building columns or freestanding supports.

Design Types:

Design Types:

- Top-Running: crane rails mounted on runway beams (e.g., wide-flange beams or trusses).

- Under-Running: Crane wheels travel on the lower flange of runway beams (common in light-duty systems).

- Material: Hot-rolled steel sections (e.g., HEB, HEA) or built-up sections for custom spans.

c) End Trucks/end carriagesWheel Configuration:

- Double-Flange Wheels: Prevent derailment in high-precision applications.

- Single-Flange Wheels: For lighter loads and cost efficiency.

- Wheel Loads: Calculated based on crane weight, payload, and impact factors.

d) Support Columns & FoundationsFreestanding vs. Building-Mounted:

- Freestanding: Requires reinforced concrete foundations and anchor bolts to resist overturning moments.

- Building-Mounted: Integrated with existing steel columns; load calculations must account for building structural capacity.

Customization remains key to addressing unique facility needs,

Contact DQCRANES and you will get reliable overhead lifting systems.

Manufacturing & Installation

Manufacturing and Quality Control: DQCRANES manufactured the 10 ton overhead cranes in our modern facilities, adhering to strict quality control procedures throughout the entire process. This ensured that the cranes met the highest standards of quality, performance, and reliability.

Installation Support:

Installation Support: Once the cranes arrived, DQCRANES provided detailed instructions and online technical support to facilitate the installation of the cranes at the client's facility. We also can send engineers for on-site supervision or installation, depending on the client's needs and the complexity of the project.

Commissioning and Training:

Commissioning and Training: DQCRANES assisted with the commissioning of the cranes to ensure they were operating correctly. We also provided training to the client's personnel on the safe and efficient operation and maintenance of the cranes.

Results and Benefits

The implementation of the DQCRANES overhead crane system provided PNC Wood Industry with significant benefits:

- Increased Productivity: The efficient and reliable overhead crane system significantly reduced material handling times, streamlined production processes, and increased overall throughput.

- Improved Safety: The robust design, advanced safety features (anti-collision systems, etc.), and ergonomic controls minimized the risk of accidents and created a safer working environment for employees.

- Enhanced Space Utilization: The customized design of the overhead traveling cranes optimized the use of available space within the facility, improving workflow and storage capacity.

- Reduced Labor Costs: The electric overhead crane system reduced the need for manual handling, leading to lower labor costs and improved operational efficiency.

- Improved Material Handling: The precise control and specialized lifting attachments ensured safe and damage-free handling of wooden boards and prefabricated parts, maintaining product quality.

- Increased Reliability: The high-quality construction and rigorous testing of the DQCRANES system ensured reliable and continuous operation, minimizing downtime and maximizing production uptime.

- Long-Term Value: The durable construction and low maintenance requirements of the cranes provided PNC Wood Industry with a long-term, cost-effective material handling solution.

Get Your Custom Crane Design & Free Quote!

DQCRANES works closely with various industries to deliver cranes that align with your facility’s layout, workflow, and budget.

Why Partner With Us?

- Fast delivery and 7/24 online support.

- Design, manufacturing, installation, and training.

- Our engineers will optimize your crane systems for specific needs.

Contact DQCRANES Today! Limited-Time Offer:

5% discount on orders placed before March 31!