55 Ton RMG Crane for Port Operations in Azerbaijan

26 Mar, 2025

Demand Background

Azerbaijan is located at the junction of Europe and Asia and is an important node country of the "Belt and Road" initiative. In recent years, its economic focus has gradually shifted from oil and gas to diversified development, focusing on port logistics, energy infrastructure, manufacturing, and transportation. These industries ' equipment upgrades and capacity expansion have driven the demand for heavy lifting machinery, especially high-capacity and high-efficiency European

Double Girder gantry cranes (35 tons to 100 tons).

- Port expansion: Baku International Port (Alat Port) 's expansion plan aims to become the largest logistics hub in the Caspian Sea region, requiring efficient loading and unloading equipment.

- Energy projects: Caspian oil and gas field development (such as the Shah Deniz gas field) and oil pipeline construction (such as the TANAP pipeline) require heavy duty cranes for modular installation.

- Renewable energy: The government plans to increase the proportion of renewable energy to 30% by 2030, and wind power projects require large cranes to hoist wind turbine components.

- Railway and logistics center: The growth in cargo transshipment demand in the Trans-Caspian International Transport Corridor (Middle Corridor) has promoted the construction of railway hubs.

Project Overview

- Client: Baku International Maritime Terminal (Azerbaijan)

- Application: Container yard stacking and bulk cargo handling at the Port of Alat, a strategic hub along the "Middle Corridor" of the Belt and Road Initiative.

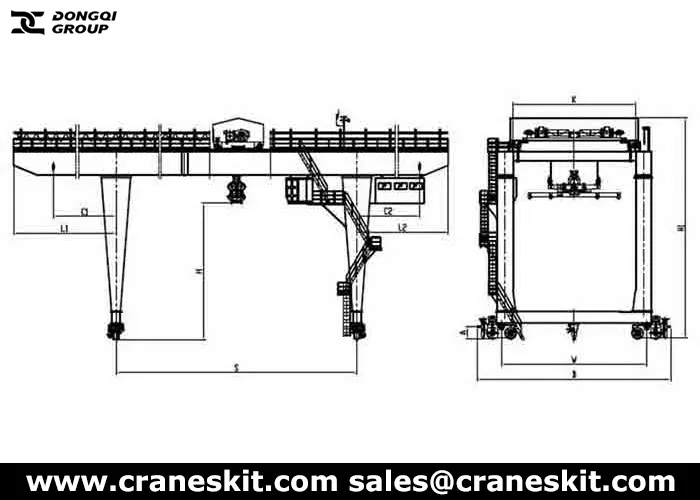

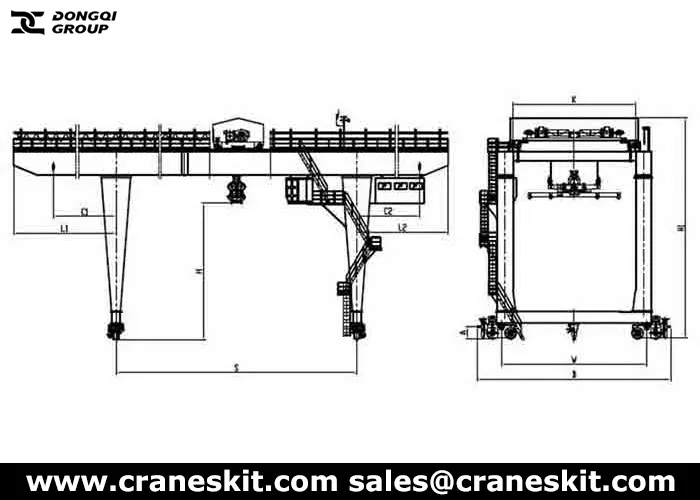

- Equipment: DQCRANES 55-ton double girder gantry crane with European standard design.

Client Requirements & Challenges

High-Efficiency Operations:

- The Port of Alat aimed to increase container throughput by 40% by 2025, necessitating 24/7 crane operations with minimal downtime.

- Challenge: Existing equipment suffered from slow hoisting speeds (≤5 m/min) and frequent motor overheating.

Harsh Environmental Conditions:

- Salt Corrosion: Proximity to the Caspian Sea caused severe corrosion on metal components.

- Wind Loads: Gusts up to 20 m/s require robust structural stability.

Space Constraints:

- Limited yard space demanded precise positioning (±10 mm accuracy) to avoid collisions with stacked containers.

Maintenance Accessibility:

- Local technicians lacked expertise in advanced crane systems, requiring simplified maintenance protocols.

RMG Crane Solution - DQCRANES

Gantry Crane Design Specifications:

Gantry Crane Design Specifications:

- Lifting Capacity: 55 tons.

- Span: 12 meters (adjustable rail gauge).

- Lifting Height: 8 meters (standard), customizable for future expansion.

- Work Class: A5 (heavy-duty cycle for port operations).

- Control System: Frequency conversion drive, IP54-rated remote control.

- Compliance: FEM standard and CE certification.

Optimized Structural Design:

- Lightweight Double Girders: Utilized high-strength Q235B carbon structural steel with FEM-optimized profiles, reducing deadweight by 15% compared to traditional designs while maintaining load capacity.

- Modular Assembly: Pre-assembled sections shipped to the site, cutting installation time by 30% (completed in 14 days).

Advanced Motion Control:

Advanced Motion Control:

- Hoisting System: Dual-speed 55-ton hoist with 0.53/3.2 m/min variable frequency control (Siemens motors), enabling rapid container handling (25 cycles/hour).

- Anti-Sway Technology: AI-based load stabilization reduced swing amplitude by 90%, critical for narrow stacking lanes.

Environmental Adaptability:

Environmental Adaptability:

- Corrosion Protection: Triple-layer epoxy coating on critical components.

- Wind-Resistant Features: Automatic rail clamps and anemometer-linked shutdown (optional).

Results & Client Feedback

Operational Outcomes:

- Efficiency Gains: Container handling speed increased to 28 cycles/hour (vs. 18 cycles previously), boosting terminal throughput by 35%.

- Reliability: 98.5% uptime in the first year, with zero critical failures.

- Cost Savings: Energy-efficient drives saved $18,000 annually in electricity costs.

- Downtime Reduction: Predictive maintenance lowered unplanned outages from 8% to 1.2% annually.

Client Feedback:"The DQCRANES RMG exceeded our expectations. Its precision in tight spaces and resilience to Caspian Sea conditions have transformed our operations. The training and IoT tools empowered our team to manage the system confidently."

Client Feedback:"The DQCRANES RMG exceeded our expectations. Its precision in tight spaces and resilience to Caspian Sea conditions have transformed our operations. The training and IoT tools empowered our team to manage the system confidently."— Mr. Elvin Mammadov, Port Equipment Manager, Baku International Maritime Terminal

RMG Crane Advantages and Applications

Advantages:

- High Efficiency: The rail-mounted design allows for efficient movement along the rail track, reducing handling time and increasing productivity.

- Space Utilization: RMGs operate vertically, maximizing available space in ports and rail yards.

- Heavy Lifting Capacity: RMGs can handle large and heavy containers, making them suitable for handling oversized cargo.

- Stability and Precision: The rail-mounted system provides superior stability and precision.

Applications:

- Container Handling: RMGs are essential for rapidly loading, unloading, and stacking shipping containers in container terminals.

- Intermodal Operations: They facilitate the transfer of containers between different modes of transport, such as ships, trucks, and trains.

- Storage Yards: RMGs are used in storage yards to stack containers in dense, organized rows, optimizing space utilization.

- Shipping and Logistics: RMGs are crucial in shipping and logistics, particularly in container terminals and large distribution centers.

How To Choose an RMG Crane from DQCRANES?

Choosing the right rail mounted gantry crane is crucial for efficient container handling in logistics and ports, rail yards, or intermodal terminals.

Contact DQCRANES to select a reliable RMG crane to ensure optimal performance for your operation.

- Load Capacity: The crane’s load capacity must match the weight of the containers, typically 20-foot (TEU) or 40-foot (FEU) containers. Make sure to select a crane that can safely handle the maximum load of your containers, taking into account both the container size and cargo weight.

- Span: The span is the horizontal distance between the crane’s rails and determines how many container rows it can handle. Choose a span that fits your container yard’s layout and allows efficient container stacking.

- Lifting Height: Lifting height is crucial for determining how many containers can be stacked. Higher lifting heights allow for taller stacking but require a crane that can handle the increased height safely and efficiently.

- Container Size (20′ or 40′): Ensure the crane is compatible with the container sizes your operation handles. Most RMG cranes are designed for both TEU and FEU containers, but it’s important to confirm this based on your primary container types.

- Containers Handled Per Hour: Crane efficiency is measured by how many containers it can move per hour. High-throughput operations require cranes with fast lifting speeds and short cycle times to meet demand.

- Spreader Orientation and Rotation: Consider whether the container spreader is parallel or vertical to the crane’s main beam and if it can rotate. Spreader rotation adds flexibility for handling containers in tight spaces, improving alignment and placement.

- Customization and Future Needs: Ensure the crane is tailored to your current needs, with room for future upgrades. Customizing the crane’s capacity, spreader features and control systems will allow you to scale operations efficiently.

If you have inquiries about RMG cranes or request a free quotation, do not hesitate to

contact us. Expect comprehensive rail gantry crane solutions and detailed quotations tailored specifically to your project.

Related Products

![MG Double Girder Gantry Crane]() MG Double Girder Gantry Crane

MG Double Girder Gantry Crane