360° Rotation Manual Jib Crane to Saudi Fabrication Facility

18 Mar, 2025

Project Overview

- Client: AN Industrial Solutions

- Industry: Warehousing & Metal Fabrication

- Location: Riyadh, Saudi Arabia

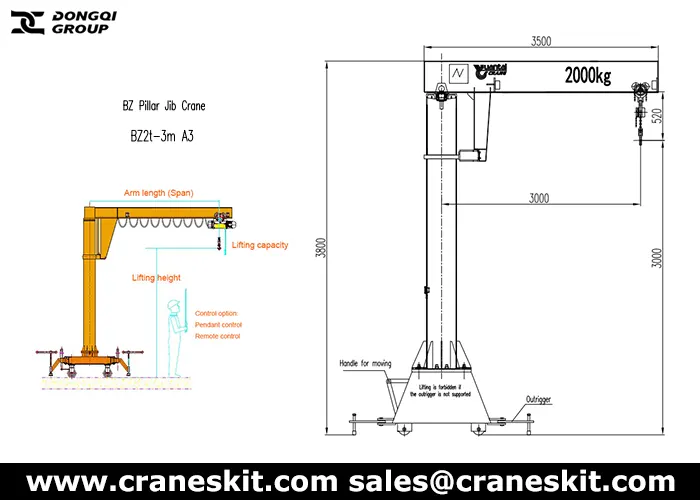

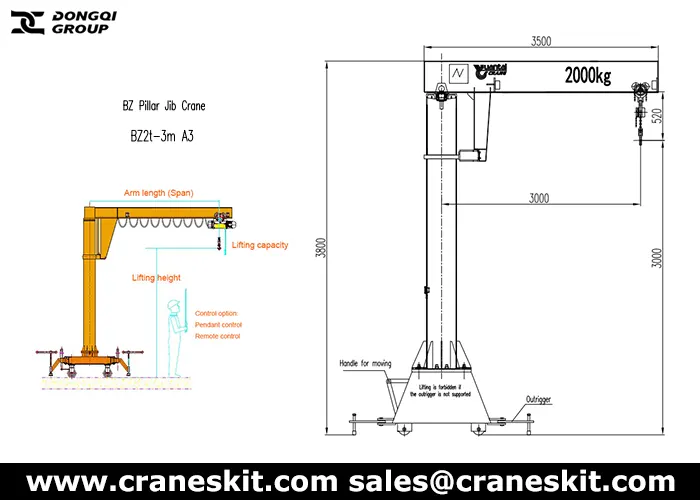

- Solution: 2 ton manually operated mobile jib crane with 3m span, 3m lifting height, and 360° rotation.

Client Background

Established in 1990, AN Industrial Solutions operates a 15,000 sqm facility in Riyadh, specializing in steel fabrication, machinery assembly, and logistics. Their operations involve handling heavy materials like steel beams (up to 2 tons), industrial machinery parts, and customized metal components. Challenges included inefficient material handling, reliance on forklifts (which lacked precision), and the need for a flexible lifting solution to serve multiple workstations without permanent infrastructure.

Client Requirements

- Capacity & Mobility: 2 ton floor jib crane lifting capacity, portable design to move between work zones.

- Manual Operation: Cost-effective, energy-efficient, and easy to use without electrical systems.

- Dimensions: 3m horizontal span and 3m lifting height to fit low-ceiling areas.

- Rotation: 360° manual rotation for precise positioning.

- Safety & Compliance: Overload protection, stability.

Contacting DQCRANES

AN discovered DQCRANES through our website on Google and requested a solution for their material handling challenges. After initial consultations, DQCRANES engineers proposed a small

portable jib crane tailored to the facility’s layout and workflow.

Custom Design Specifications

Structural Design:

Structural Design:

- Base: Heavy-duty steel frame with four lockable swivel castors (5-inch diameter) for smooth mobility.

- Boom: Reinforced I-beam construction (3m span) with a welded support collar for 360° rotation.

- Mast: Adjustable bolted connections to fine-tune vertical height (fixed 3m lifting height).

Manual Operation:

- Chain hoist system (2-ton capacity) with ergonomic hand chain lever.

- Rotational resistance calibrated for smooth manual slewing.

Safety Features:

- Mechanical load limiter to prevent overloads.

- Anti-tip brackets and dual brake castors for stability.

- Safety latch hooks.Reinforced base plate with ground anchors.

Key Design Features

- Portability: Lightweight, and easily repositioned by two workers.

- Durability: Hot-dip galvanized finish for corrosion resistance in Riyadh’s arid climate.

- Precision: Rotational torque optimized for controlled manual operation.

Client Feedback & Order Approval

AN’s engineering team praised the mobile floor

jib crane design’s simplicity, and cost-effectiveness. After a virtual demonstration and minor adjustments to the base dimensions, a formal purchase order was signed in January 2025.

Manufacturing & Export

- Production Timeline: 4 weeks (February 2025).

- Export Details: Shipped via sea freight from Qingdao, China, to Riyadh.

- Documentation: CE certification, load test reports, and operation manuals included.

Installation & Training

DQCRANES provided remote installation support via video call, guiding AN’s technicians through the assembly. The 2 ton portable jib crane was operational within 6 hours. A local partner conducted on-site safety training for 12 staff members.

Post-Installation Benefits

- Efficiency Gains: Reduced material transfer time by 40%.

- Labor Savings: Eliminated need for 3 forklift operators.

- Flexibility: Crane serves 8+ workstations across the facility.

- Safety: Zero incidents reported since deployment.

Manual Jib Crane vs Electric Jib Crane

| Product |

Manual Jib Crane |

Electric Jib Crane |

| Cost |

Lower upfront and operational costs |

Higher initial and maintenance costs |

| Load capacity |

Up to 5 tons (light/moderate loads) |

Up to 16 tons (heavy-duty) |

| Operation Speed |

Slower, labor-dependent |

Faster, automated |

| Precision |

Limited by manual effort |

High precision with variable speeds |

| Energy Needs |

None |

Requires electricity power |

| Maintenance |

Minimal (no motors) |

Regular servicing of electrical parts |

| Portability |

Often mobile (castor wheels) |

Usually fixed or semi-stationary |

| Best Use Case |

Small workshops, occasional use |

Heavy industry, high-frequency tasks |

Manual Jib Crane

Operation:

- Powered by human effort (chain hoists, hand-pulled rotation).

- No electricity or motors are required.

Key Features:

- Load Capacity: Typically 0.25-5 tons (ideal for light loads).

- Rotation: Manual slewing (360° rotation via swivel bearings or pivot joints).

- Mobility: Often mounted on mobile bases for portability.

Advantages:

- Cost-Effective: Lower upfront cost (no motors, wiring, or power systems).

- Energy-Independent: No electricity needed, ideal for remote areas or facilities with power limitations.

- Simple Maintenance: Fewer components reduce repair costs and downtime.

- Ease of Use: Minimal training is required.

- Portability: Mobile versions can be repositioned easily.

Disadvantages:

- Labor-Intensive: Requires physical effort to lift, lower, and rotate loads.

- Slower Operation: Not ideal for high-frequency or time-sensitive tasks.

- Limited Precision: Manual control may lack the accuracy needed for delicate positioning.

Ideal For:

- Small workshops, warehouses, or fabrication shops.

- Occasional lifting tasks (e.g., loading/unloading trucks, repositioning machinery).

- Budget-conscious projects or facilities with limited electrical infrastructure.

Motorized Jib Crane

Operation:

Operation:

- Powered by electric motors for hoisting and rotation systems.

- Controlled via pendant, remote, or automated systems.

Key Features:

- Load Capacity: 0.5-16 tons (suitable for medium and heavy-duty applications).

- Rotation: Motorized 360° rotation with adjustable speed.

- Lifting Speed: Variable speeds for precise load handling.

Advantages:

- High Efficiency: Faster lifting/rotation, ideal for repetitive tasks.

- Precision Control: Smooth, accurate positioning (critical for delicate loads).

- Reduced Labor: Minimizes physical strain on workers.

- Automation-Friendly: Can integrate with IoT systems or programmable logic controllers (PLCs).

- Higher Capacity: Suitable for heavy industrial applications.

Disadvantages:

- Higher Cost: Expensive upfront investment (motors, wiring, controls).

- Energy Dependency: Requires consistent power supply.

- Complex Maintenance: Motors and electrical components need regular servicing.

- Installation Requirements: May need reinforced flooring or fixed foundations.

Ideal For:

- High-volume manufacturing plants, assembly lines, or foundries.

- Heavy-load applications (e.g., steel mills, automotive factories).

- Facilities requiring frequent, precise lifts (e.g., positioning CNC machine parts).

DQCRANES Solutions for Saudi Arabia!

We supply both manual and motorized jib cranes for sale to Saudi industrial needs:

- Custom Engineering: Adapt cranes to your facility’s layout.

- Competitive Pricing: Direct factory pricing with no middlemen.

- Warranty: Standard 1–2 years on structural components.

- Technical Support: Remote troubleshooting or local partner assistance in Saudi Arabia.

- Spare Parts Availability: Confirm access to replacement parts (e.g., bearings, motors).

Contact DQCRANES today, you will get a suitable jib crane that enhances productivity, safety, and ROI for your Saudi facility!

Related Products