At DQCRANES, we pride ourselves on delivering high-quality, customized lifting solutions to meet the diverse needs of industries worldwide. Recently, we designed, manufactured, and exported 2 sets of 16 ton

single girder overhead cranes for vehicle maintenance and commissioning operations in Lahore, Pakistan.

Project Overview

DQCRANES' experienced team of engineers and technicians meticulously designed and manufactured the cranes, paying close attention to every detail. The following steps were involved in the project execution:

- Design and Engineering: Detailed engineering drawings were created to ensure precise manufacturing and assembly.

- Manufacturing: The crane components were manufactured using state-of-the-art machinery and techniques.

- Quality Control: Rigorous quality control measures were implemented to guarantee the highest standards of workmanship.

- Assembly: The crane was assembled in a controlled environment to ensure accuracy and efficiency.

- Testing: The crane underwent extensive testing to verify its performance and safety.

- Packaging and Shipping: The crane was carefully packaged and shipped to Lahore, Pakistan, using specialized transportation methods.

- Installation and Commissioning: DQCRANES' experienced technicians provided on-site installation and commissioning services to ensure smooth integration into the client's facility.

- Training: The client's operators received comprehensive training on safe and efficient crane operation.

Project Details

Understanding the Client's Needs:

The client, a leading vehicle maintenance and commissioning company based in Lahore, approached us with a specific set of requirements. Their operations demanded a reliable and efficient lifting solution capable of handling heavy loads while ensuring precision and safety. The cranes were intended to facilitate the repair, assembly, and commissioning of vehicles, which required a robust yet flexible design.

After a thorough consultation with the client, our sales team identified the following key requirements:

- A lifting capacity of 16 tons to handle heavy vehicle components.

- A single girder overhead configuration to optimize space utilization in the workshop.

- High operational efficiency with smooth and precise control mechanisms.

- Compliance with safety standards to ensure operator and equipment safety.

- Durability to withstand the demanding conditions of a vehicle maintenance environment.

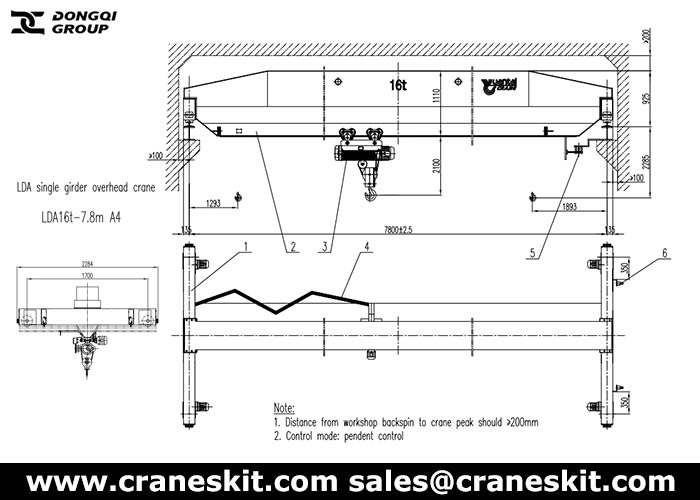

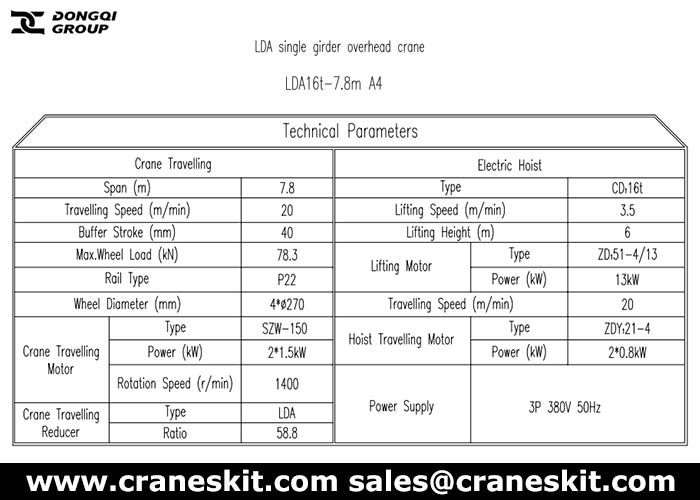

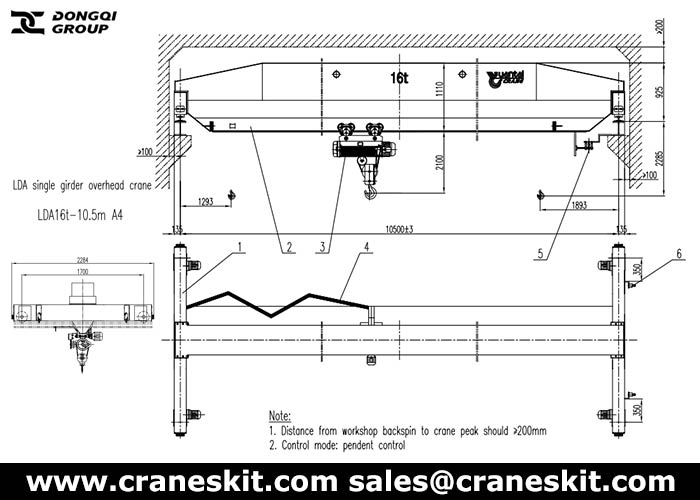

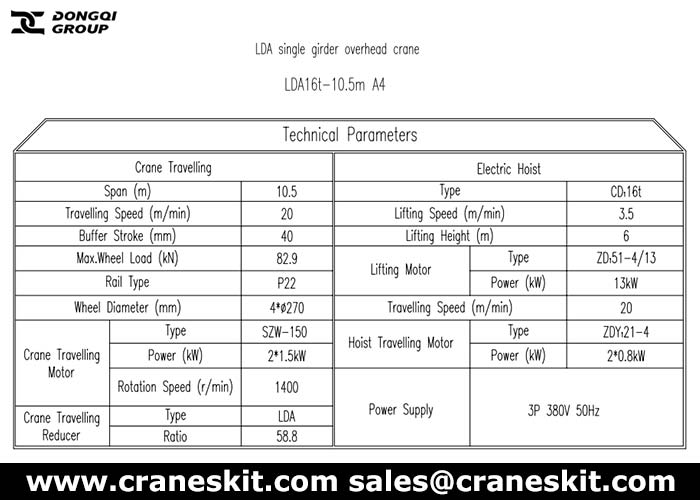

Overhead Crane Design Solution:

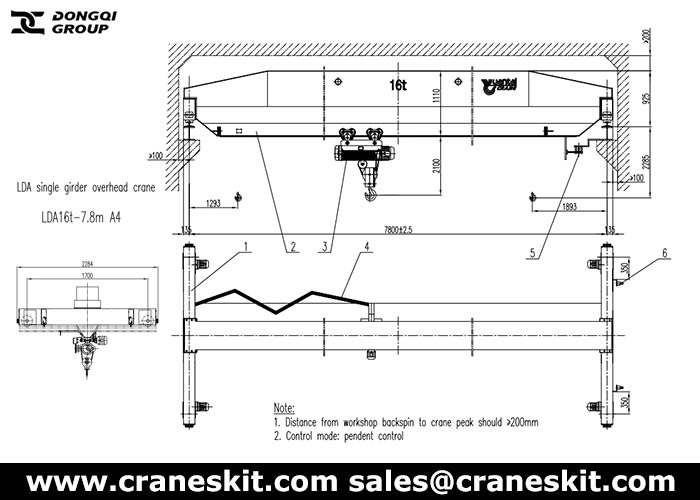

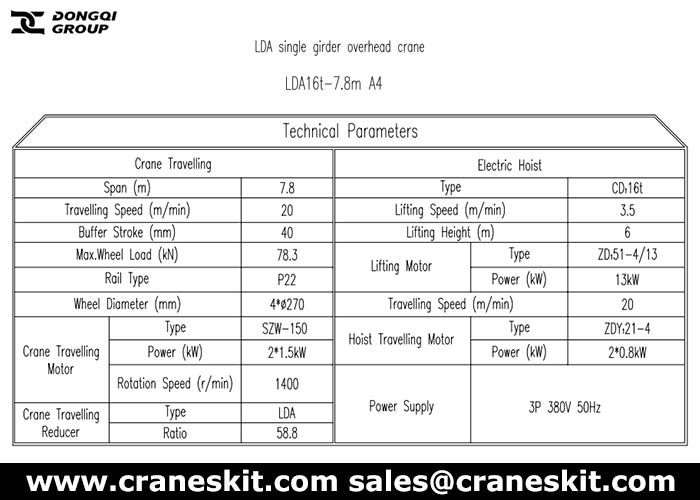

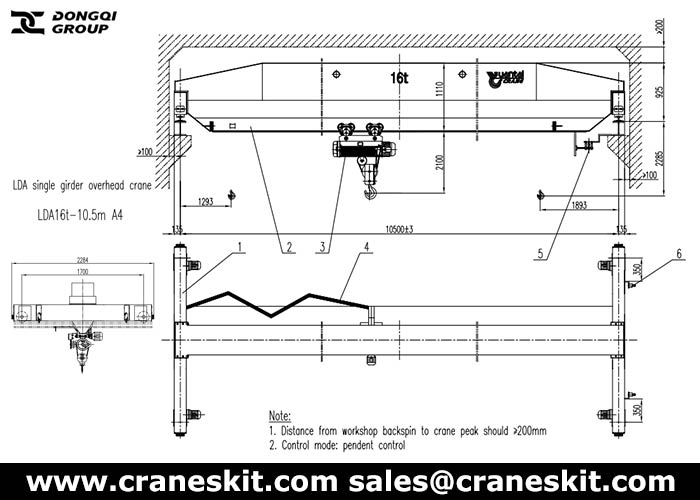

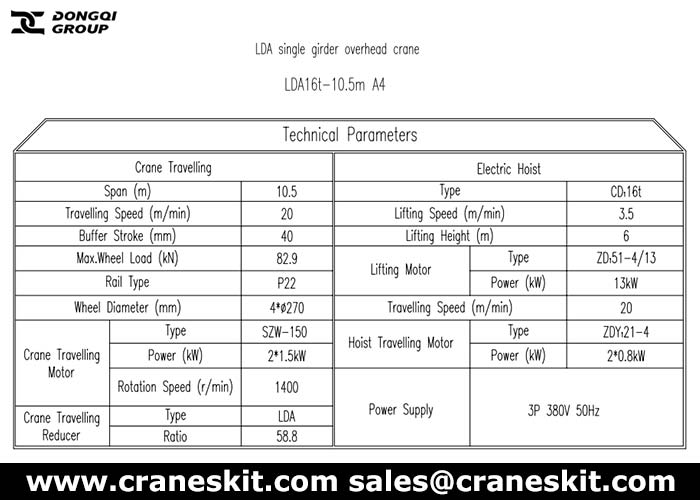

With these requirements in mind, our engineering team got to work on designing a crane that would not only meet but exceed the client's expectations. The 16 ton single girder overhead crane was meticulously engineered to deliver optimal performance while maintaining structural integrity.

- High-Quality Materials: The crane girders were constructed using premium-grade Q235B carbon structural steel and three-coat painting to ensure durability and longevity under heavy-duty operations.

- Compact Design: The single girder configuration was chosen to maximize the use of available space in the workshop while maintaining a high load capacity.

- Advanced Hoisting Mechanism: Equipped with a wire rope electric hoist, the crane offers smooth lifting and lowering operations with precise control.

- Safety Features: The single girder EOT crane is outfitted with advanced safety systems, including lifting and traveling limit switches, overload protection, emergency stop functionality, anti-collision sensors, etc.

- Ease of Operation: A user-friendly pendent control system was integrated to allow operators to handle loads efficiently and safely.

Production and Delivery:

Once the design was finalized, our manufacturing team brought the project to life in our state-of-the-art facility. Every component of the 16 ton overhead

bridge cranes were fabricated with precision and subjected to rigorous quality control checks.

To guarantee performance reliability, the crane underwent extensive testing in simulated operational conditions. This included load tests, motion tests, and safety system evaluations. Only after passing all these tests with flying colors was the crane deemed ready for shipment.

Export and Installation:

Our cooperating logistics team ensured the overhead crane was securely packed and transported to Lahore, Pakistan, without any delays or damage. All necessary documentation for customs clearance was handled efficiently to facilitate smooth delivery.

Upon arrival at the client's facility, our experienced installation team collaborated with local technicians to assemble and install the crane. The installation process was completed promptly, minimizing downtime for the client’s operations.

Training and After-Sales Support:

At DQCRANES, we believe that delivering a product is just the beginning of our relationship with the client. To ensure seamless adoption of the new equipment, we provided comprehensive training sessions for the client’s operators. These sessions covered everything from basic operations to advanced troubleshooting techniques.

In addition, we offered ongoing after-sales support, including regular maintenance services and quick access to spare parts. Our dedicated customer service team remains available around the clock to address any concerns or queries from the client.

Project Outcomes

The successful installation and commissioning of the 16 Ton Single Girder Overhead Crane has significantly improved the efficiency and productivity of the vehicle maintenance facility in Lahore. The crane has enabled the facility to handle heavy-duty lifting tasks easily and precisely, reducing downtime and improving overall operational performance.

Why Choose DQCRANES?

- Product Range and Customization:

Diverse Product Line: DQCRANES offers a wide range of cranes and hoists, including overhead cranes,

gantry cranes,

jib cranes, and electric hoists. This variety ensures you can find the right equipment for your specific needs.

Customization Options: We specialize in customized solutions, allowing you to tailor cranes to your exact requirements, whether it's lifting capacity, span, or special features.

Advanced Technology: DQCRANES leverages advanced European technology in their research and development, resulting in high-quality, reliable products.

Stringent Quality Control: We maintain strict quality control standards throughout the manufacturing process to ensure consistent performance and durability.

- Experience and Expertise:

Industry Experience: With years of experience in the crane industry, DQCRANES has a deep understanding of material handling solutions.

Expert Team: Our team of engineers and technicians can provide expert advice and support, from initial consultation to after-sales service.

- Cost-Effective Solutions:

Competitive Pricing: DQCRANES offers competitive pricing without compromising on quality.

Long-Term Value: Their durable and reliable products can reduce maintenance costs and downtime, providing long-term value.

Customer-Centric Approach: DQCRANES prioritizes customer satisfaction and strives to build long-lasting relationships.

Excellent Customer Support: We offer comprehensive after-sales support, including installation, maintenance, and repair services.

Contact DQCRANES

DQCRANES is very proud to have played a role in supporting industry development in Lahore, Pakistan, looking forward to continuing our mission of empowering industries worldwide with innovative lifting solutions. If you're seeking a reliable partner for your material handling needs, DQCRANES is here to help you achieve your goals with precision and professionalism.

For more information about our cranes and services, please feel free to contact us via

E-mail or WhatsApp:

+86 18838184113.