Client

The pipe manufacturing industry is characterized by its demanding environment, where heavy materials and precision handling are daily challenges. A prominent pipe manufacturing company in South Africa was facing problems in its production process, including:

- Manual Material Handling: Repetitive and labor-intensive manual lifting of heavy pipes, increasing the risk of workplace injuries.

- Inefficient Production: Slow and cumbersome material handling processes, impacting overall productivity.

- Ergonomic Concerns: Straining physical demands on workers, leading to fatigue and potential health issues.

Requirements

The South African pipe manufacturer approached DQCRANES with a clear set of requirements: they needed a KBK light crane system that was not only robust and reliable but also flexible enough to adapt to their specific operational needs.

The client's existing setup involved manual handling and outdated lifting equipment, which posed both safety risks and operational inefficiencies. They required a

KBK crane system that could seamlessly integrate into their current workflow, improve safety standards, and increase throughput.

Solution

DQCRANES, a leading supplier of material handling equipment, with its extensive experience in designing customized lifting solutions. After a thorough analysis of the client's operations and site conditions (including workspace dimensions, load capacities, and operational needs) by online video, DQCRANES proposed a set of 1 ton free standing cranes. This

workstation crane systems were specifically engineered to meet the unique demands of the pipe manufacturing process.

Unlike traditional overhead cranes requiring fixed runways, freestanding cranes offer several advantages:

Unlike traditional overhead cranes requiring fixed runways, freestanding cranes offer several advantages:

- Flexibility: They can be easily positioned and relocated within the workshop to accommodate changing workflows.

- Cost-effective: They eliminate the need for extensive building modifications or additional support structures.

- Compact footprint: Their self-supporting design minimizes space requirements within the workshop.

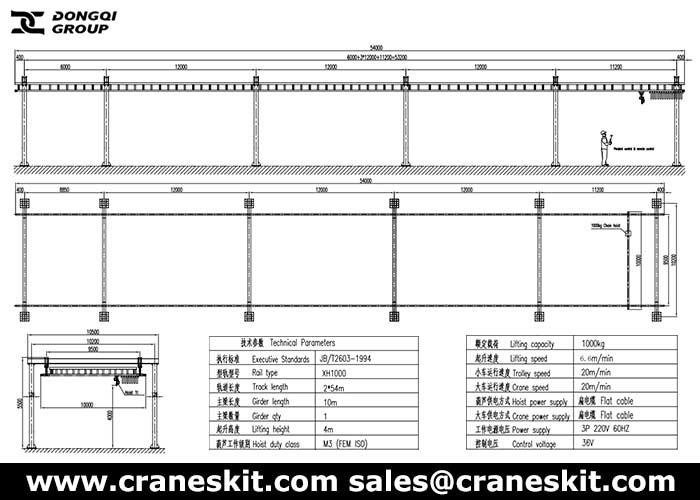

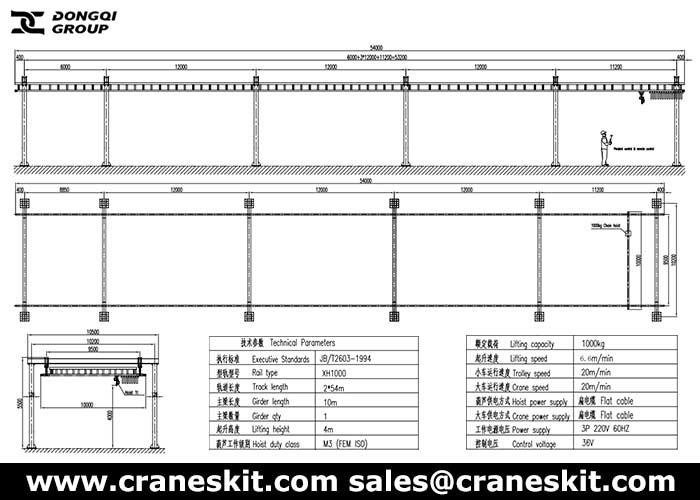

| Lifting capacity |

1000kg |

| Lifting height |

4m |

| Track length |

2*54m |

| Hoist type |

electric chain hoist |

| Lifting speed |

6.6m/min |

| Travling speed |

20m/min |

| Crane power |

Flat cable |

| Power supply |

3-phase, 220V, 60Hz |

| Control voltage |

36V |

KBK Crane Design Features

- Modular Design: The freestanding cranes boast a modular design, allowing for easy installation and future scalability. This feature ensures that as the client's production needs grow, the crane system can be expanded without significant overhauls.

- Enhanced Safety: Safety is paramount in any manufacturing environment. The free standing workstation cranes are equipped with advanced safety features, including overload protection and emergency stop functions, significantly reducing the risk of accidents.

- Precision Handling: The 1 ton KBK cranes are equipped with electric chain hoists, designed for precise load positioning, crucial for handling pipes that require exact alignment during manufacturing processes. This precision reduces material damage and enhances product quality.

- Ergonomic Efficiency: Recognizing the importance of operator comfort, DQCRANES incorporated ergonomic pendent controls that minimize operator fatigue and improve productivity.

- Durability and Reliability: Constructed with high-grade materials, these cranes are built to withstand the rigors of the manufacturing environment, ensuring long-term reliability and minimal maintenance.

Impact

The installation process was meticulously planned and executed by DQCRANES' team of experts to minimize disruption to the client's ongoing operations. Once operational, the impact of the new workstation cranes was immediate and profound.

The client reported a significant reduction in handling times, which directly translated into increased production throughput. Moreover, the enhanced safety features contributed to a safer working environment, reducing the incidence of workplace injuries.

The flexibility of the modular design also allowed the client to reconfigure their production line with ease, adapting swiftly to changing market demands without incurring additional costs.

Types of Freestanding bridge cranes in South Africa

DQCRANES offers a variety of freestanding bridge crane solutions to cater to diverse lifting needs in South Africa. Here are some popular options:

- Single Girder Freestanding Bridge Cranes:

single girder cranes are characterized by a single bridge beam supported by end trucks. These cranes are typically used for lighter loads and shorter spans. They are cost-effective and require less material, making them an economical choice for many businesses. In South Africa, single girder cranes are popular in manufacturing and warehousing environments where space and budget constraints are considerations.

- Double Girder Freestanding Bridge Cranes:

For heavier loads and longer spans,

Double Girder Cranes are the preferred choice. These cranes feature two bridge beams, offering greater strength and stability. The additional girder allows for higher lifting capacities and can accommodate more complex lifting equipment. Industries such as steel production and heavy machinery manufacturing often rely on double girder systems.

- Workstation Freestanding Bridge Cranes:

Workstation cranes are designed for precision tasks in smaller work areas. They provide an ergonomic solution for repetitive lifting tasks, improving productivity and reducing worker fatigue. These cranes are ideal for assembly lines, automotive workshops, and other environments where precise handling of materials is crucial.

- Gantry Freestanding Bridge Cranes:

gantry cranes are distinctive due to their leg supports, which allow them to operate without being attached to a building structure. This type is highly versatile and can be moved around a facility as needed. Gantry cranes are particularly useful in outdoor applications or in large indoor spaces where flexibility is key.

Contact DQCRANES

DQCRANES offers competitive pricing on all its lifting equipment, including freestanding bridge cranes. To get a free quote for your specific needs in South Africa, please contact DQCRANES via

sales@craneskit.com. Our experienced sales team will be happy to discuss your project and provide a tailored solution.