Crane slings are generally can be divided in the following types: Chain sling, wire rope sling, nylon slings, synthetic web, cargo nets, synthetic web, etc. Each type of crane sling has its own merits and shortcomings. In the following, the most frequently used crane slings will be put in length.

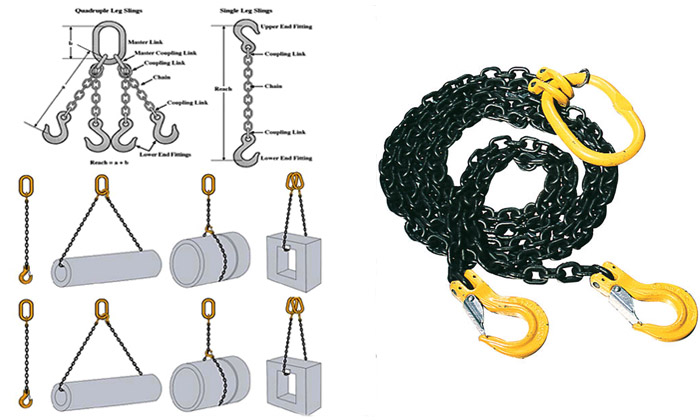

Crane Chain Sling

- Chain sling is the most commonly used crane sling for the advantages on high strength and durability.

- Chain sling can be used according to their “grade”, which categorizes them by the order of tensile strength.

Grade 10 chain slings

- 25% higher load capacity than grade 8 enables smaller chain dimensions to be employed

- Cost savings (up to 30%) and weight savings (up to 50%)

- Longer service life thanks to higher strength

- Any possible combination of the components in our catalogue can be assembled

- Also available as round sling harnesses

Grade 12 chain slings

- Maximum durability for low deadweight thanks to

- Intelligent chain profile and use of high-performance chain steel

- Optimum strength and durability at high and low temperatures

- Longer service life

- Fewer failures due to wear

- Lower weight per tonne of load capacity

- Simple visual identification

Grade 8 chain slings

- Reliable inspection and repair of your existing grade 8 chain slings

- Advice on the configuration of additional chain slings

- Refurbishment of existing chain slings

- Supply of matching spare parts

Notice to chain sling

The chain slings are banned to use when the chain slings are found with defective welds, questionable welds, bending chain links or elongation chain links, cracked or deformed master and coupling links, etc. When the identification tags of the chain slings are miss, it is also forbidden to put into use. Any deformation, cracking or wearing is found, the chain slings are not ready to use. And any other unsafe condition is observed, it is banned to use.

Crane Wire Rope Sling

- Wire rope slings are basically a group of wires, twisted and wrapped around a core.

- The wire rope slings are extensively used for lifting loads.

Notice to wire rope slings

Wire rope slings are not allowed to use when find five broken wires in on strand in on lay, kinking, crushing, bird caging, heat damage, attachment cracking, deforming or wearing, etc.

Synthetic Sling

- Synthetic slings is good in strength, flexibility and elasticity, light in weight and easy to handle.

- Synthetic slings are used to handle slippery loads for its ability to provide good friction which can keep the loads from damages.

- Synthetic slings must be used in the proper working environment, to make the safety of the sling, for they are usually made from polypropylene, polyester, polyamide, nylon or any combination of these.

- Synthetic slings should be inspected accordingly for they are easy to be damaged and deterioration.

Notice to synthetic slings

The synthetic slings are not qualified to use when the synthetic sling are found acid or caustic burns, age deterioration, melting or charring on the surface, colored thread exposure due to snags, tears, or cuts, etc. And also the synthetic slings are also forbidden to use when the identification tags are unreadable or missing, etc.

When select the crane slings, the following factors should be considered, the single specification, the size of the objects or loads, weight, shape, and the way of the hoisting, etc.

Crane Slings Selection

- The lifting capacity must be adequate and work well with the proper length of the used sling.

- When more than one slings are used at same time, the slings must belong the same category.

- The crane sling application environment must be considered for it make affects the safety of the slings.

Factors affects the sling safety

The safety of the crane slings are affected by the following factors:

1) Size, Weight, and Center of Gravity of the Load.

By the center of the gravity of the load, it means the crane hook must be directly over the center of gravity point. If NOT, it may result in to dangerous tilting and uneven stress to the sling leg.

2) Rated Capacity of the Sling.

The capacity of the crane sling varies with the sling types, sizes, and hitch types, etc. Notice the older crane slings must be used with caution.

3) History of Care and Usage.

The sling-related accidents are mainly resulted from the mishandling and misuse of the slings. Proper care of the crane slings is important for maximum service and safety. The crane slings must be protected with wood blocking, burlap padding and cover saddles to prevent sharp bends and cutting edges.

Crane slings working rules

For the use of crane slings, the following rules should be followed:

- Crane slings overhead loading is totally prohibited.

- The broken crane slings is not allowed to be used.

- Do not pull a sling from a suspended load under tension.

- Crane slings with knots should not be used.

- Do keep the lifting loads away from working staffs.

- Do keep the lifting loads away from the obstructions.

- Do keep the crane sling from the edges of the loads.