KBK-LD type flexible modular single girder suspension crane comprises standard linear track and other auxiliary standard parts. The trolley traveling part at both ends of the main beam can be run on two tracks perpendicular to the direction of the main beam, the single beam can be used with each type of fixed chain hoist, and the special KBK driving device can drive the hoist to run along the direction of the main beam.

This KBK

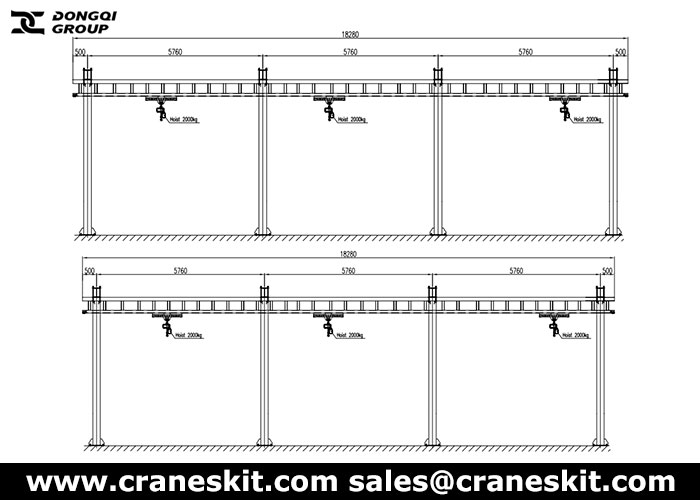

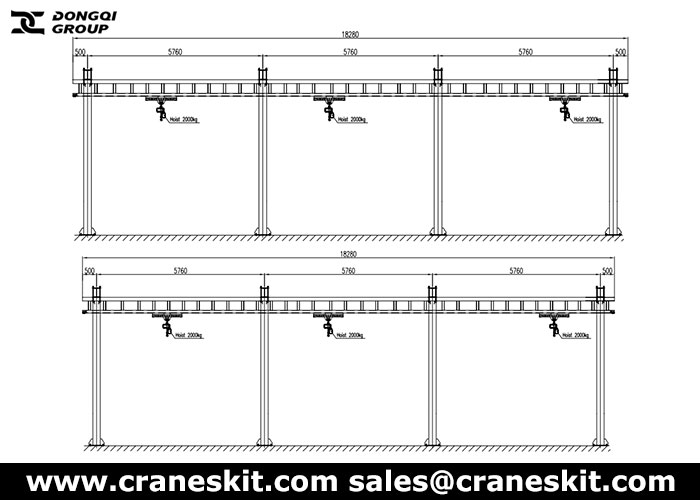

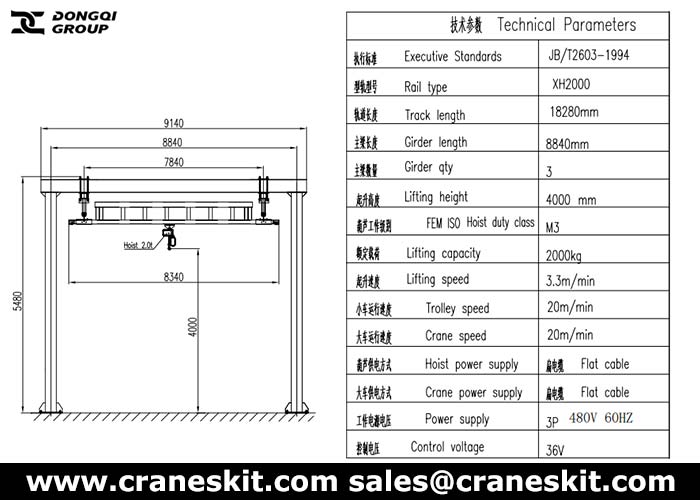

workstation crane systems are used for plane material transportation and can be used in workshops or warehouses. Due to its special flexibility and degree of freedom, the flexible modular single beam suspension crane can be inclined to run on the track, it can also walk on the track with variable span, and it can also run on two concentric circular curved tracks which are not possible for other kinds of lifting products. The maximum span of a flexible composite single-beam suspension crane is 10 meters and the maximum lifting capacity is 2000kg.

Case

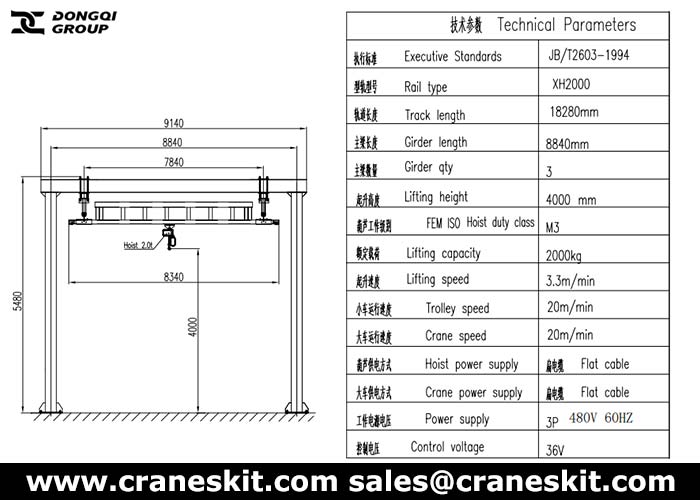

DQCRANES supplied 3 sets of KBK cranes to a new manufacturing facility in Las Palmas, Canary Islands, Spain to meet their growing demands. The order was booked on September 11, 2024, with delivery and installation scheduled for October 13, 2024.

The 3 sets of free standing cranes for sale to enhance the new facility's manufacturing capabilities. The client specializes in designing, manufacturing, and supplying electrical transformers and related equipment for various industrial applications. From the arrival of new materials to assembly, packaging, and dispatch of finished goods, all processes rely heavily on lifting and moving operations. The cranes' lifting capacities range from 500kg to 2000kg and include flexible features such as

electric chain hoists and trolleys, supporting faster load cycle times and ease of operation.

Feedback

"To ensure reliability and long-term performance, we selected cranes known for their quality and durability. We are confident that our investment in DQCRANES’ material handling equipment will not only minimize downtime but also enhance our operational longevity for many years to come,"

said the client - Javier Manrique, Purchasing Manager.

KBK Crane System VS Traditional overhead crane

- Reduce plant cost: The equipment does not need the help of the plant corbel, in the design of the plant, you can minimize the bearing capacity of the plant column design to greatly reduce.

- No need to change the plant structure: For the existing plant, it can be added at any time according to the production needs, without any modification to the original structure of the plant.

- Less idle equipment: The carrying space can be covered according to the needs, and accurate shooting can be conducted to minimize idle waste of equipment.

- More accurate positioning: Light and small structure, easy operation, accurate positioning.

- More energy-saving and environmental-friendly: Small power, low energy consumption, more energy saving and environmental protection.

- Low operating noise: Simple structure, low failure rate, greatly reduce the scope of equipment failure.

- High comprehensive benefit: The track system is maintenance-free, the electric components are maintained conveniently and the cost is low. Reduce the time and labor cost caused by equipment failure, with high comprehensive benefit.

KBK Workstation Cranes Benefits

Optimum space utilization:

- Overhead, area-serving load transport

- Optimum utilization of space thanks to minimum approach dimensions

- Suspension from existing workshop ceilings or roof structures

- Require no additional supports for the crane runway

Convenient handling:

Convenient handling:

- Simple, safe, and reliable handling

- Favorable installation dimensions

- Customer-specific and cost-effective solutions for workshops – also in limited sections

- Versatile applications thanks to modular system design (e.g. latching arrangements with KBK double suspension monorails for crane trolley transfer)

- Can also be employed as manipulator cranes – optimum design for use in state-of-the-art handling systems. Strong performance

- Modular system design. Rated for loads weighing up to 3,000 kg

- Maximum possible hook paths by arranging the hoist between the crane girders

- Maximum span dimensions utilizing multiple suspensions (cranes operating on more than two runways) – to cover extensive storage and production areas

Buy KBK Workstation Cranes from DQCRANES

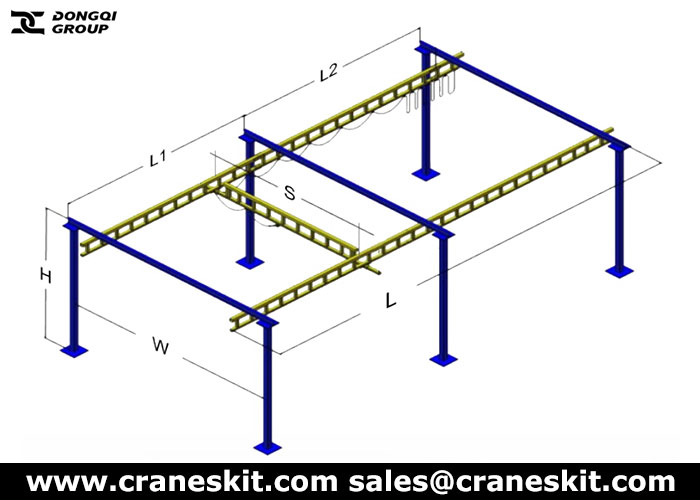

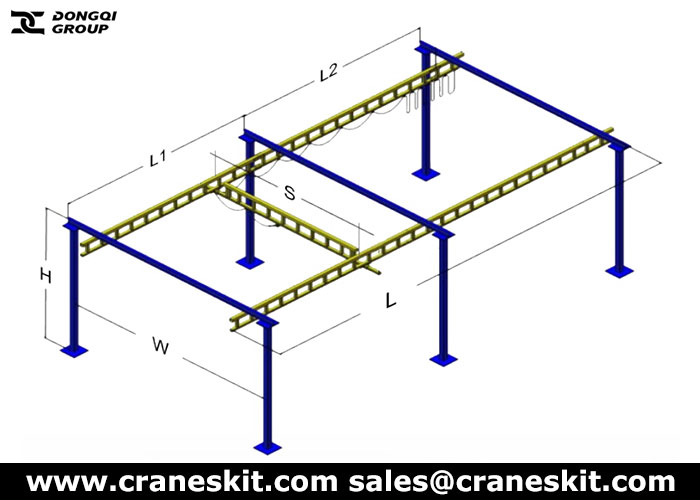

DQCRANES provides customized workstation cranes made of steel and aluminum to meet your specific needs.

Contact us to send us your inquiry here. Our engineers are ready to provide you with help and advice.

- Lifting capacity: __Kg

- W(S)=__m, H=__m, L=__m, L1=__m, L2=__m

- Hoist type: Electric chain hoist or wire rope hoist or Manual chain hoist?

- Crane travel type: Electrical type or Manual type?

- Voltage: ____V____Hz____Phase (If electrical type)

- Control Mode: Remote control or Pendant control?

- How many KBK cranes are running on the same track?

- Transportation: tell us the sea port name near you, we can quote you shipping freight.