In the world of industrial lifting solutions, customization, and precision are key to meeting clients' unique demands across various industries. DQCRANES, a leading manufacturer and supplier of crane systems, recently designed and delivered a tailored 2-ton floor-mounted

jib crane for an electronics manufacturing workshop in Penang, Malaysia.

Client Background

The client, a prominent electronics manufacturing workshop based in Penang, Malaysia, specializes in producing high-precision components for consumer electronics. Their production processes involve frequently handling delicate and heavy materials, necessitating reliable and efficient lifting solutions to streamline operations and ensure workplace safety.

Client Requirements

The client approached DQCRANES with the following requirements:

- A lifting solution with a capacity of 2 tons to handle their heaviest components.

- A jib crane with a valid radius of 3 meters to cover specific workstations within their production floor.

- A lifting height of 4 meters to accommodate the vertical space needed for their operations.

- A 180-degree rotation capability to allow flexibility in material handling across the designated area.

- A durable and low-maintenance system suitable for continuous use in an electronics manufacturing environment.

jib crane design - DQCRANES Custom Crane Solution

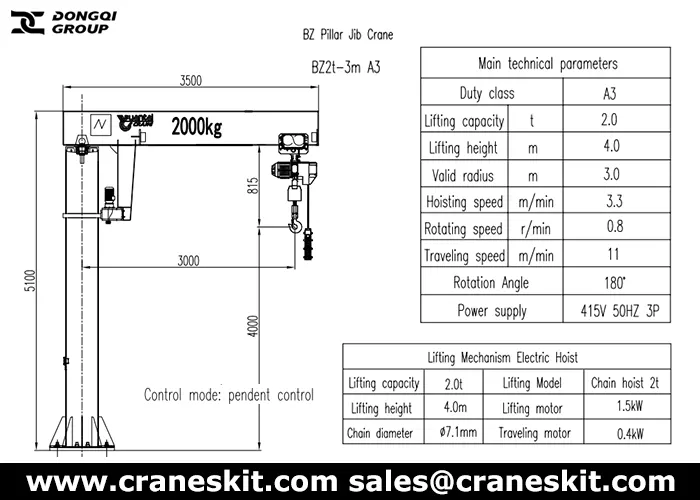

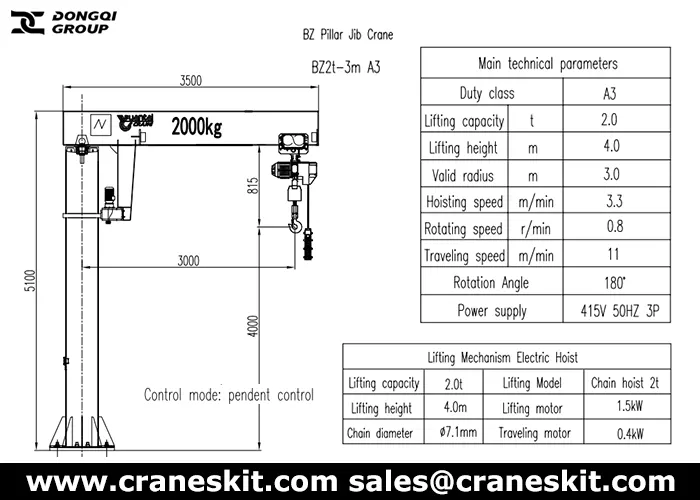

After a thorough analysis of the client’s needs and workspace layout, DQCRANES proposed a customized 2 ton

floor mounted jib crane. The solution was meticulously designed to meet the client’s operational requirements while ensuring optimal performance, safety, and cost-effectiveness.

- Load Capacity: The floor mounted crane is engineered to safely lift loads to 2 tons, ensuring it can handle the heaviest components used in the client’s manufacturing processes.

- Valid Radius: With a 3-meter working radius, the jib crane provides ample coverage for the designated workstations, enabling seamless material handling within the specified area.

- Lifting Height: The 4-meter lifting height allows for smooth vertical movement, accommodating the client’s operational needs and ensuring compatibility with their existing equipment.

- Rotation Capability: The 180-degree rotation feature offers flexibility and efficiency in handling materials across multiple workstations. This semi-circular range of motion ensures that operators can quickly and accurately position loads as needed.

- Robust Construction: The 2 ton jib crane is built using high-quality materials to ensure durability and reliability under continuous use. The structure is designed to withstand the demanding conditions of an industrial environment while requiring minimal maintenance.

- Ease of Operation: Equipped with user-friendly pendant controls, the electric jib crane allows operators to perform lifting tasks with precision and ease, reducing downtime and improving productivity.

- Safety Features: The jib crane system includes advanced safety mechanisms such as overload protection, emergency stop functions, and secure anchoring to prevent accidents and ensure compliance with international safety standards.

Design and Manufacturing

DQCRANES adopted a collaborative approach throughout the project lifecycle, working closely with the client to ensure all specifications were met. The process included:

- Initial Consultation: Detailed discussions with the client to understand their operational requirements, workspace constraints, and long-term goals.

- Customized Design: Using advanced design software, DQCRANES’ engineering team developed a tailored solution that aligned with the client’s specifications while optimizing performance and cost-efficiency.

- Precision Manufacturing: The jib crane for sale Malaysia components were manufactured using state-of-the-art machinery and subjected to rigorous quality control measures to ensure compliance with industry standards.

- Pre-Delivery Testing: Before shipment, the crane underwent comprehensive testing at DQCRANES’ facility to verify its performance, safety features, and adherence to design specifications.

- On-Site Installation: A team of skilled technicians was dispatched to Penang for the installation process. The crane was securely anchored to the workshop floor and integrated seamlessly into the client’s production environment.

- Training and Support: DQCRANES provided on-site training for the client’s operators to ensure safe and efficient use of the jib crane. Additionally, ongoing technical support was made available as part of the company’s commitment to customer satisfaction.

Impact

The delivery of the 2-ton floor-mounted jib crane brought numerous advantages to the electronics manufacturing workshop in Malaysia:

- Improved Efficiency: The 2 ton floor jib crane significantly reduced manual handling time, allowing operators to focus on core production tasks and boosting overall productivity.

- Enhanced Safety: By minimizing manual lifting and incorporating advanced safety features, the floor mounted jib created a safer working environment for employees.

- Cost Savings: The durable construction and low-maintenance design of the jib crane eith electric chain hoist resulted in reduced operational costs over time.

- Operational Flexibility: The 180-degree rotation capability enabled seamless material handling across multiple workstations, enhancing workflow efficiency.

- Scalability: The modular design of the rotating jib crane allows for future upgrades or modifications as the client’s operational needs evolve.

Client Testimonial

“The DQCRANES jib crane perfectly balanced precision and durability. We’re already planning to deploy additional units in our new facility.”— Mr. Tan, Production Manager

Why DQCRANES?

- Expertise in Custom Solutions

DQCRANES specializes in designing tailored material handling solutions that align with the unique requirements of diverse industries. Our ability to customize equipment ensures optimal performance and compatibility with existing workflows.

Every product from DQCRANES is manufactured using high-quality materials and adheres to international standards. This guarantees durability, safety, and long-term reliability.

From consultation to delivery and installation, DQCRANES provides end-to-end support. Our team of experts ensures that every project is executed seamlessly, with minimal disruption to the client’s operations.

With years of experience serving clients worldwide, DQCRANES has built a reputation for excellence in crane manufacturing and material handling solutions. Our track record speaks volumes about their ability to deliver results.

DQCRANES leverages cutting-edge technology and innovative engineering practices to produce cranes that enhance operational efficiency while maintaining safety and ease of use.

If you’re looking for reliable and customized material handling solutions for your business, DQCRANES is here to help.

Contact us today to discuss your requirements.