Client Background

Constructora Argentia S.A., a leading construction firm based in Buenos Aires, specializes in infrastructure projects across Argentina. Their operations involve frequent relocation of heavy machinery and materials (e.g., steel beams, concrete panels) across multiple sites. Faced with logistical challenges and tight deadlines, the company sought a portable lifting solution that could be easily transported and assembled in dynamic environments.

Client Requirements

Constructora Argentia outlined the following needs:

- Capacity: 10-ton lifting capacity for heavy construction materials.

- Mobility: Easy assembly/disassembly for portability across sites.

- Design: Double girder structure for stability and heavy-duty performance.

- Dual Lifting Speed: Dual-speed hoist (0.7 m/min for precision, 7.0 m/min for efficiency).

- Safety & Compliance: Adherence to Argentinian safety standards (ISO certifications).

DQCRANES’ Design Solution

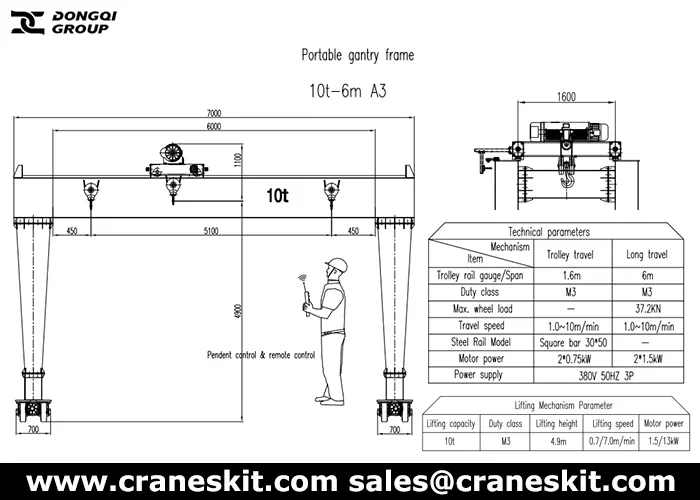

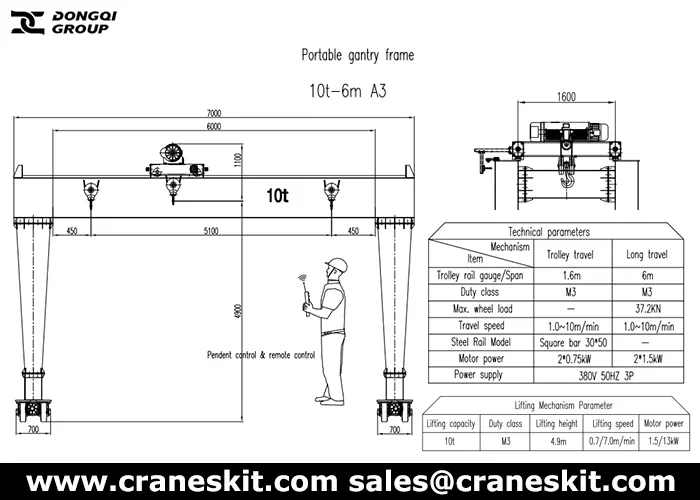

DQCRANES proposed a 10 ton

portable gantry crane featuring a double girder design, equipped with a double girder hoist trolley. This configuration was chosen for its superior stability and load distribution capabilities. The crane was designed to offer dual lifting speeds of 0.7/7.0 m/min, providing the client with the flexibility to handle both delicate and heavy-duty tasks efficiently.

Mobility Features:

Mobility Features:

- H-frame fixed height legs (4.9m lifting height) for various terrain.

- Quick-release bolts and detachable sections for easy transport.

- Hoist System: Dual-speed electric hoist trolley (0.7/7.0 m/min), traveling speed 1.0~10 m/min.

- Safety: Overload protection, emergency stop, and limit switches.

Technical Specifications:

Technical Specifications:

| Lifting Capacity |

10 Tons |

| Span |

6m (Trolly rail gauge 1.6m) |

| Lifting Height |

4.9m |

| Lifting Speed |

0.7 m/min (low) / 7.0 m/min (high) |

| Traveling Speed |

1.0~10 m/min |

| Power Supply |

380V/50Hz (3-phase) |

| Material |

High-strength Q235B steel |

| Control |

Pendent control & Remote control |

10 Ton Gantry Crane Design Features:

- Robust steel construction for durability and longevity.

- Precision-engineered hoist trolley for smooth operation.

- Advanced safety mechanisms to ensure operator and equipment safety.

- Easy assembly and disassembly for enhanced portability.

Contract & Manufacturing

After approving the design, Constructora Argentia signed a contract in Q4 2024. DQCRANES completed manufacturing in 8 weeks, using CNC machining and rigorous quality checks.

Factory Inspection & Testing

The client’s engineers visited DQCRANES’ factory in China to witness load testing (125% of capacity) and operational trials. The crane performed flawlessly, earning immediate approval.

Packaging & Delivery

The crane was disassembled into 8 crates for cost-effective sea freight. Export-grade packaging ensured zero damage during the 35-day transit to Buenos Aires.

Client Feedback

“DQCRANES’ portable gantry crane revolutionized our workflow. The dual-speed hoist and portability exceeded expectations.” — Carlos Mendez, Project Manager, Constructora Argentia.

Remote Installation Support

- Step-by-step multilingual manuals.

- Video guides and live Zoom sessions for assembly.

- 24/7 technical support during commissioning.

Gantry Crane Applications in Argentina

At DQCRANES, gantry cranes for sale in Argentina are versatile lifting solutions widely used across Argentina’s industrial sectors due to their adaptability, mobility, and ability to handle heavy loads in diverse environments. Below are the primary industries in Argentina where gantry cranes play a critical role, along with their specific applications:

Construction & Infrastructure

Applications:

- Lifting and positioning steel beams, prefabricated concrete panels, and construction materials.

- Assembling bridge components in road/rail projects.

- Loading/unloading heavy machinery (e.g., excavators, bulldozers).

Preferred Crane Types:

- Portable Gantry Cranes: Easy to transport between sites.

- Adjustable Height/Width Cranes: Adapt to varying site layouts.

- Double Girder Cranes: For heavy loads (10+ tons) and long spans.

Agriculture & Agro-IndustryApplications:

- Handling bulk grains, fertilizers, and livestock feed in silos or storage facilities.

- Loading/unloading heavy farming equipment (tractors, harvesters).

- Moving packaged goods (sugar, soybeans) in processing plants.

Preferred Crane Types:

- Light-Duty Gantry Cranes: For small to medium loads (1–5 tons).

- Outdoor Gantry Cranes: Weather-resistant designs for rural environments.

Mining & QuarryingApplications:

- Transporting ore, minerals, and raw materials in open-pit mines.

- Maintenance of mining machinery (crushers, conveyor systems).

- Loading trucks/trains with extracted materials.

Preferred Crane Types:

- Heavy-Duty Double Girder Cranes: For 20–50+ ton loads.

- Rubber-Tired Gantry Cranes (RTG): Mobility on rough terrain.

Manufacturing & AutomotiveApplications:

- Assembling vehicle components in automotive plants.

- Moving heavy machinery parts in factories.

- Storing and retrieving materials in warehouses.

Preferred Crane Types:

- single girder cranes: Cost-effective for workshops.

- Electric Hoist Gantry Cranes: Precision lifting for assembly lines.

Ports & LogisticsApplications:

- Loading/unloading shipping containers at ports (e.g., Buenos Aires, Rosario).

- Transshipment of goods between trucks, trains, and ships.

- Handling heavy cargo (timber, steel coils) in logistics hubs.

Preferred Crane Types:

- Container Gantry Cranes: For ISO-standard containers.

- Rail-Mounted Gantry Cranes (RMG): High-capacity stacking in terminals.

Oil & GasApplications:

- Assembling pipelines and drilling equipment.

- Maintenance of refinery machinery.

- Transporting heavy valves and pressure vessels.

Preferred Crane Types:

- Explosion-Proof Gantry Cranes: For hazardous environments.

- Customized Gantry Cranes: For 50+ ton loads in refineries.

How to Buy Gantry Cranes from DQCRANES?

As a leading manufacturer in the crane industry, DQCRANES offers a variety of gantry cranes designed for different applications and environments. Here are some main factors to consider in buying a gantry crane from DQCRANES:

- Load Capacity and Type: The first consideration should be the load capacity required for your operations. Gantry cranes come in various sizes and capacities, ranging from small, portable models to large, heavy-duty systems capable of lifting several tons. Understanding the maximum weight and type of materials you need to lift is crucial in selecting the appropriate crane.

- Span and Height: The span (the distance between the runway rails or legs) and the height of the crane are critical dimensions that must align with your workspace and lifting needs. Measure your facility's dimensions accurately to ensure that the crane can operate efficiently within the available space.

- Operational Environment: Consider the environment in which the gantry crane will operate. Factors such as indoor vs. outdoor use, exposure to harsh weather conditions, and potential corrosive elements can influence the choice of materials and coatings for the crane. DQCRANES offers models with weatherproofing and corrosion resistance features for challenging environments.

- Mobility Requirements: Depending on your operational needs, you may require a stationary or mobile gantry crane. Mobile gantry cranes offer flexibility and can be easily moved around your facility, while stationary models provide stability for fixed-location tasks.

- Customization Options: DQCRANES provides customization options to tailor the crane to specific operational requirements. Consider any additional features you might need, such as specialized hooks, remote controls, or automation capabilities that can enhance productivity and safety.

- After-Sales Support and Service: A reputable manufacturer like DQCRANES should offer robust after-sales support, including warranty coverage, maintenance services, and readily available spare parts. Assess the level of customer service provided to ensure ongoing support for your investment.

- Installation and Training: Finally, consider the installation process and any training required for your staff to operate the crane safely and efficiently. DQCRANES may offer installation services and training programs to facilitate a smooth transition.

At DQCRANES, we have a selection of gantry crane types and other crane systems that can benefit your business. If you've got questions or request a free quote, please don't hesitate to

contact us, and we can help you choose the variation most suited for your business needs.