Overhead Crane in Pakistan - Ex Proof 5 Ton Overhead Cranes in Karachi

08 Apr, 2025

- Oil & Gas: Refineries and storage facilities handling flammable materials (e.g., Port Qasim, Karachi, and CPEC-related projects).

- Chemical & Pharmaceutical: Facilities using volatile substances (e.g., Lahore and Faisalabad industrial zones).

- Mining & Minerals: Coal mines in Sindh and Balochistan with combustible dust risks.

- Textiles: Mills in Punjab and Karachi process flammable fibers.

- Power Generation: Coal-fired plants and LNG facilities requiring hazardous-area cranes.

Project Overview

- Client: A leading chemical manufacturing plant in Karachi, Pakistan, specializing in industrial solvents and flammable chemical production.

- Objective: Upgrade material handling infrastructure with explosion-proof cranes to enhance operational safety in hazardous zones.

- Scope: Design, manufacture, and installation of 3 double girder explosion-proof overhead cranes with varying spans and a 5-ton lifting capacity.

Client Requirements

Hazardous Environment Compliance:

- Zone 1/21 (ATEX/IECEx) certification for areas with flammable vapors and dust.

- Resistance to corrosive chemicals and high humidity.

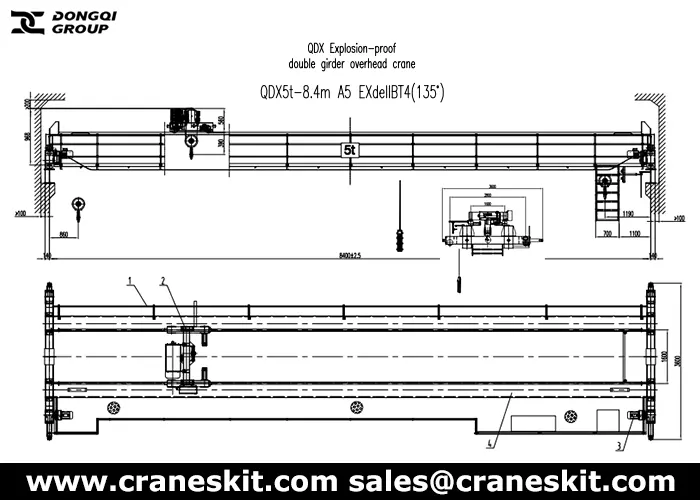

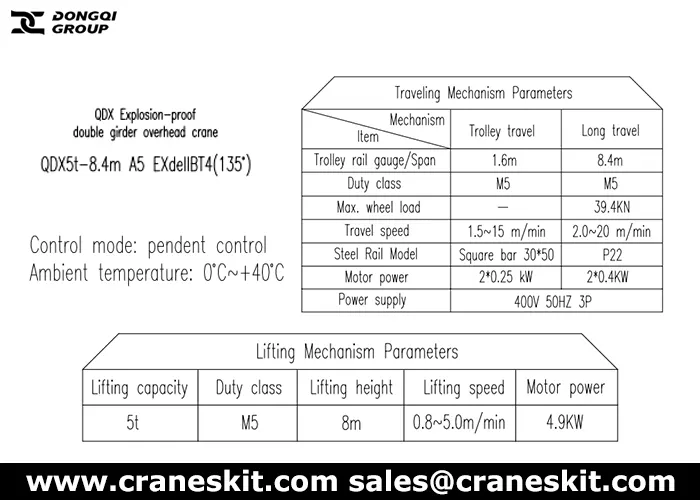

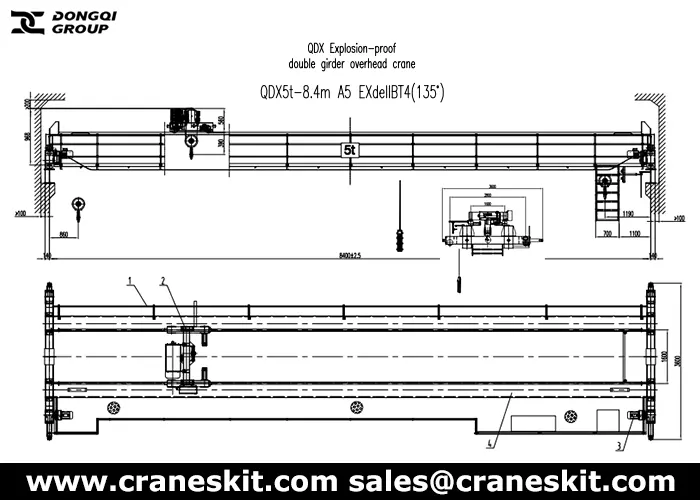

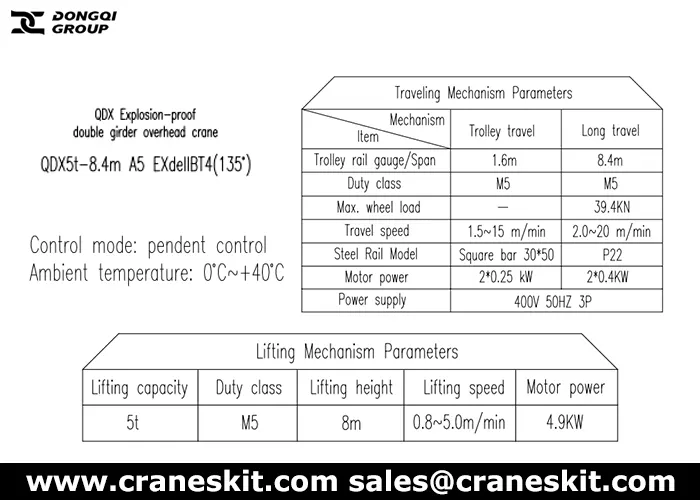

Technical Specifications

- Capacity: 5 tons per ex proof crane.

- Spans: 5.4m, 7m, and 8.4m to cover multiple production bays.

- Lifting Height: 8m to accommodate tall storage racks and reactors.

- Control: Pendant and radio remote operation for flexible use.

Design Standards

- Explosion-proof motors, enclosed wiring, spark-resistant brakes, and corrosion-resistant materials.

- Corrosion-resistant coatings for Pakistan’s coastal climate.

5 Ton Explosion Proof Crane Solution in Pakistan

Double Girder Structure:

Double Girder Structure:

- Enhanced stability for precise handling of chemical drums and reactors.

Explosion-Proof Components:

- Motors and hoists rated Exdb IIBT4 (suitable for gas/dust explosions).

- Anti-spark trolley wheels and brass-bushed hooks.

- IP55-rated electrical enclosures to prevent moisture ingress.

Span Variants:

Span Variants:

- Crane 1: 5.4m span for tight reactor bays.

- Crane 2: 7m span for mid-sized storage zones.

- Crane 3: 8.4m span for bulk material handling.

Lifting System:

- QDX double girder hoist trolley with dual-speed lifting (0.8–5 m/min), traveling speed 1.5-15 m/min.

Safety Features:

Safety Features:

- ATEX Certification: All electrical components (e.g., limit switches, pendant stations) are certified for Zone 1.

- Fail-Safe Mechanisms: Overload protection, emergency stop buttons, and thermal monitoring for motors.

- Corrosion Protection: Epoxy-painted girders and stainless steel fasteners to withstand Karachi’s salty air.

Manufacturing and Delivery

- Crane Girders and Components were prefabricated in DQCRANES’ ISO-certified facility in China, with third-party inspections for quality assurance.

- These three explosion-proof cranes were shipped in modular sections to reduce on-site assembly time.

Installation and Training

- Local partners in Karachi handled civil work (runway beams and power supply).

- Installation was completed in 12 days with minimal disruption to plant operations.

- On-site training for 10 operators and maintenance staff on safety protocols and troubleshooting.

Installation Challenges & Solutions

Challenge 1: Tight installation timelines due to the plant’s 24/7 production schedule.Solution: Pre-assembled girders and night shifts for installation.

Challenge 2: High ambient temperatures (up to 45°C) risking motor overheating.Solution: Motors equipped with integrated cooling fans and thermal sensors.

Results & Benefits

- Safety: Zero incidents reported in hazardous zones post-installation.

- Efficiency: 30% faster material transfer between production units.

- Durability: No corrosion or electrical faults observed after 6 months of operation.

Client Feedback

The client praised DQCRANES for delivering cranes that exceeded expectations:

“DQCRANES’ expertise in explosion-proof crane design was evident. The cranes have operated flawlessly, improving our safety and productivity. Their after-sale support has been exceptional.” — Plant Manager, Pakistani Chemical Plant

Explosion Proof Cranes and Hoists for Sale in Pakistan

Here are the types of explosion-proof cranes and hoists offered by DQCRANES tailored for hazardous environments in Pakistan:

1. Explosion-Proof Overhead Cranesa. Single Girder Explosion-Proof Overhead Cranes

- Capacity: 1–20 tons

- Span: 3m–22.5m

- Lifting Height: Up to 20m

Features:

Features:

- Compact design for low-ceiling facilities.

- ATEX-compliant pendant/remote controls.

- Overload protection and emergency stop systems.

- Stainless steel fasteners for coastal corrosion resistance.

Applications: Pharmaceutical labs, textile mills, small-scale chemical storage.

b. Double Girder Explosion-Proof Overhead Cranes

- Capacity: 1–100 tons

- Span: 5m–35m (customizable)

- Lifting Height: Up to 30m

Features:

Features:

- Ex d/IIC T4-certified motors and electrical components.

- Anti-spark trolley wheels and brass-bushed hooks.

- IP65 protection for dust/moisture resistance.

- Dual-speed hoisting (0.8–8 m/min).

- Corrosion-resistant epoxy coating for humid climates.

Applications: Oil refineries, chemical plants, LNG terminals.

2. Explosion-Proof gantry cranes

- Capacity: 5–50 tons

- Span: 5m–30m

- Mobility: Rubber-tired or rail-mounted options.

Features:

Features:

- Zone 1/21 certification (gas/dust environments).

- Explosion-proof limit switches and wiring.

- Heat-resistant brakes for high-temperature areas.

Applications: Ports, outdoor storage yards, mining sites.

3. Explosion-Proof Hoistsa. Explosion Proof wire rope hoists

- Capacity: 1–50 tons

- Lifting Speed: Single speed and Dual speed (variable frequency drive).

Features:

Features:

- Ex d IIC T4/T5-rated gearbox and motor.

- Flame-retardant cable and thermal overload protection.

- IP65 enclosure for harsh environments.

b. Explosion Proof Chain Hoists

- Capacity: 0.5–10 tons

- Lifting Height: Up to 12m

Features:

Features:

- Spark-resistant alloy chains.

- Manual or electric operation (ATEX-certified).

Applications: Maintenance workshops, packaging units.

4. Explosion-Proof workstation cranes

- Capacity: 0.25–3 tons

- Span: 2m–10m

Features:

Features:

- Modular aluminum/steel design.

- Explosion-proof pendant controls.

Applications: Laboratories, pilot plants, flammable material R&D.

Why DQCRANES?

- Expertise: 20+ years in explosion-proof crane manufacturing for chemical and oil industries.

- Customization: Ability to tailor spans, speeds, and control systems.

- Global Standards: Designs meet ISO, CE, and IECEx norms.

- After-Sales: Remote monitoring and local technical partnerships in Pakistan.

Conclusion

DQCRANES’ tailored solution addressed the Pakistani chemical plant’s safety, compliance, and operational needs. The explosion-proof cranes and hoists have enhanced productivity, reduced risks, and set a benchmark for hazardous environment lifting solutions.

Contact DQCRANES for tailored explosion-proof crane solutions in hazardous environments.

Related Products