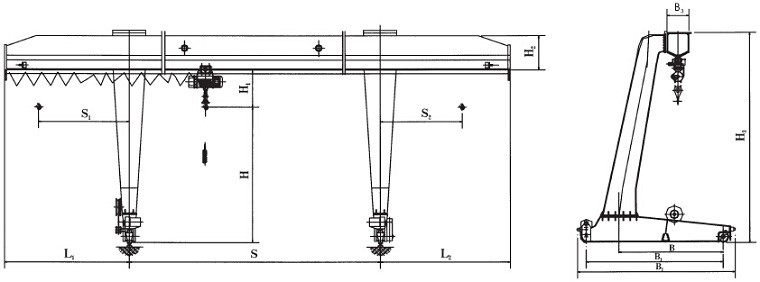

A-type Gantry crane consists of gantry frame steel structure, trolley, crane traveling mechanism, electrical system and other major components.

To facilitate transport, loading, unloading and installation on site, on the main components set up lugs, hanging holes, etc., used for lifting. The intensity and location of these lugs and hanging holes fully consider lifting safety and convenience.

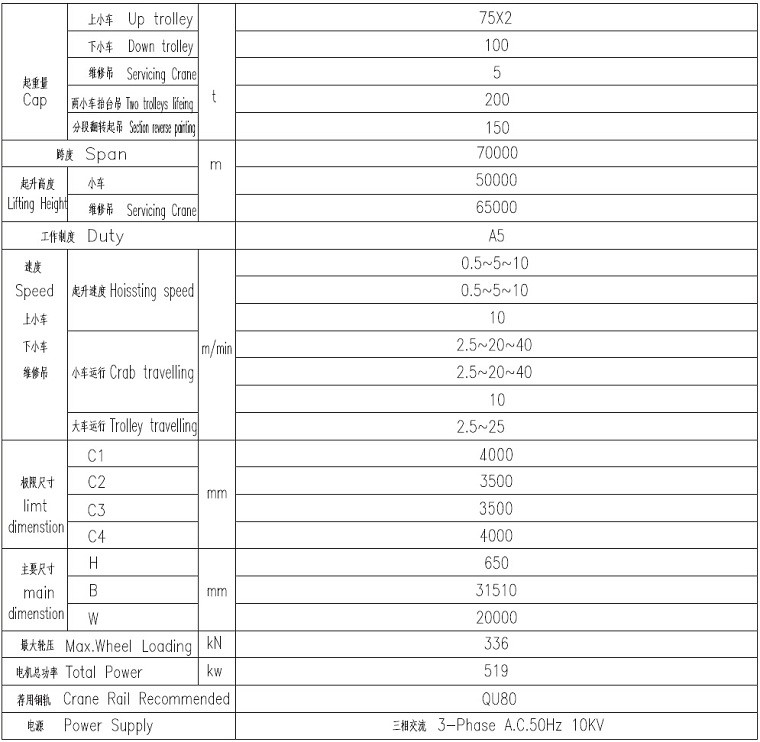

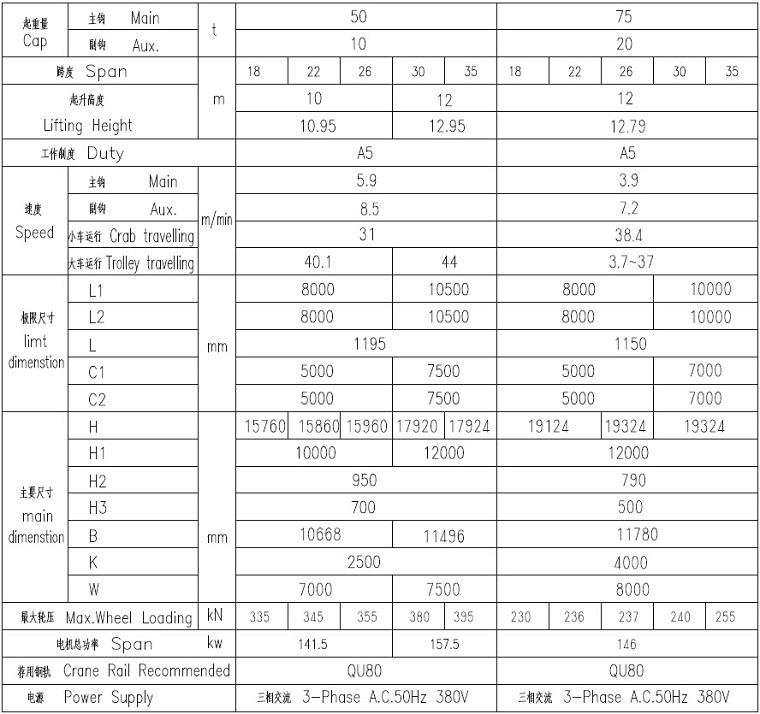

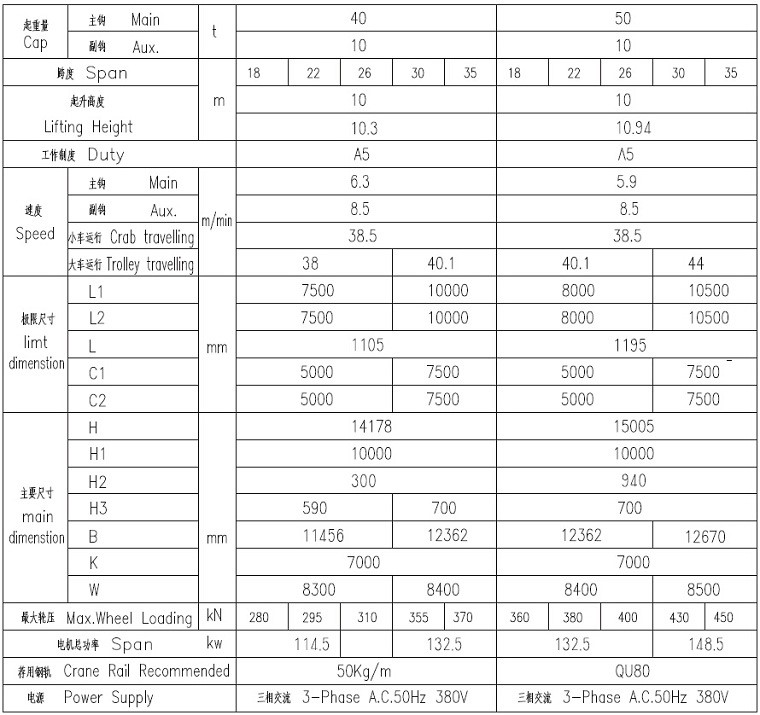

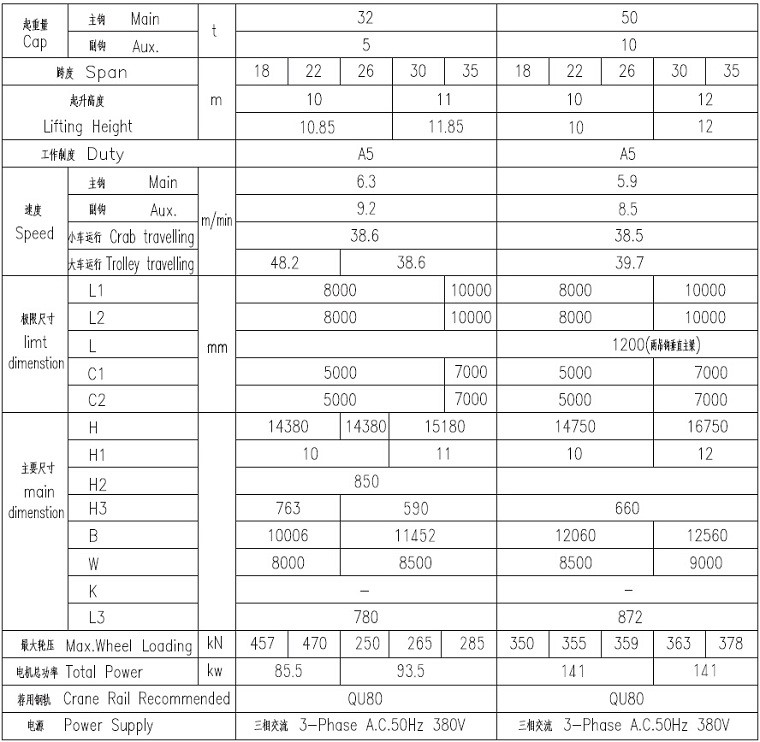

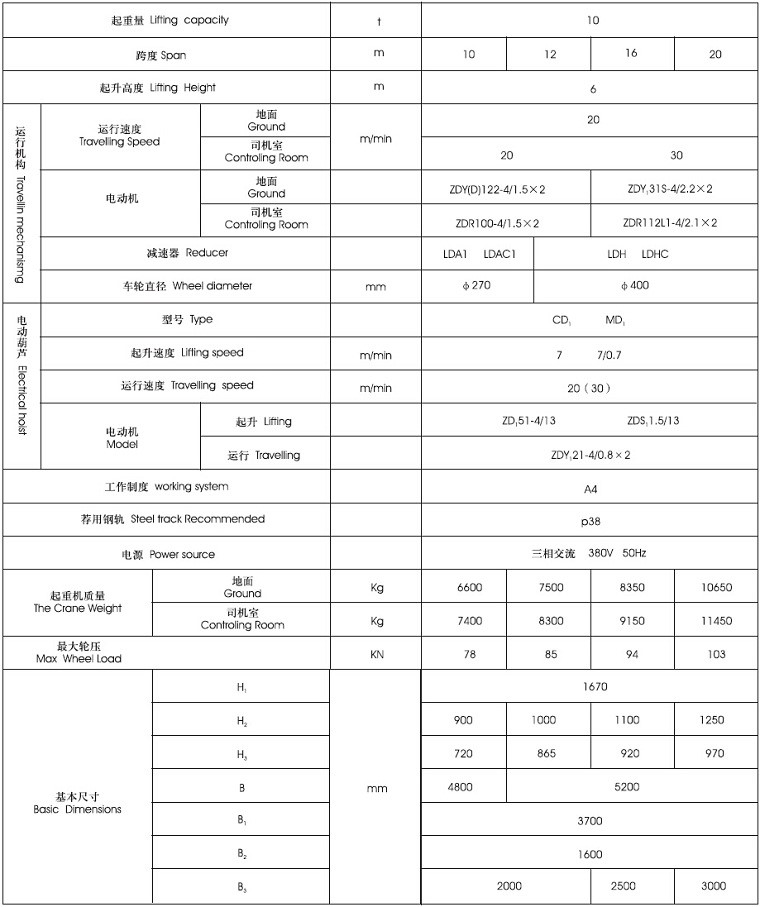

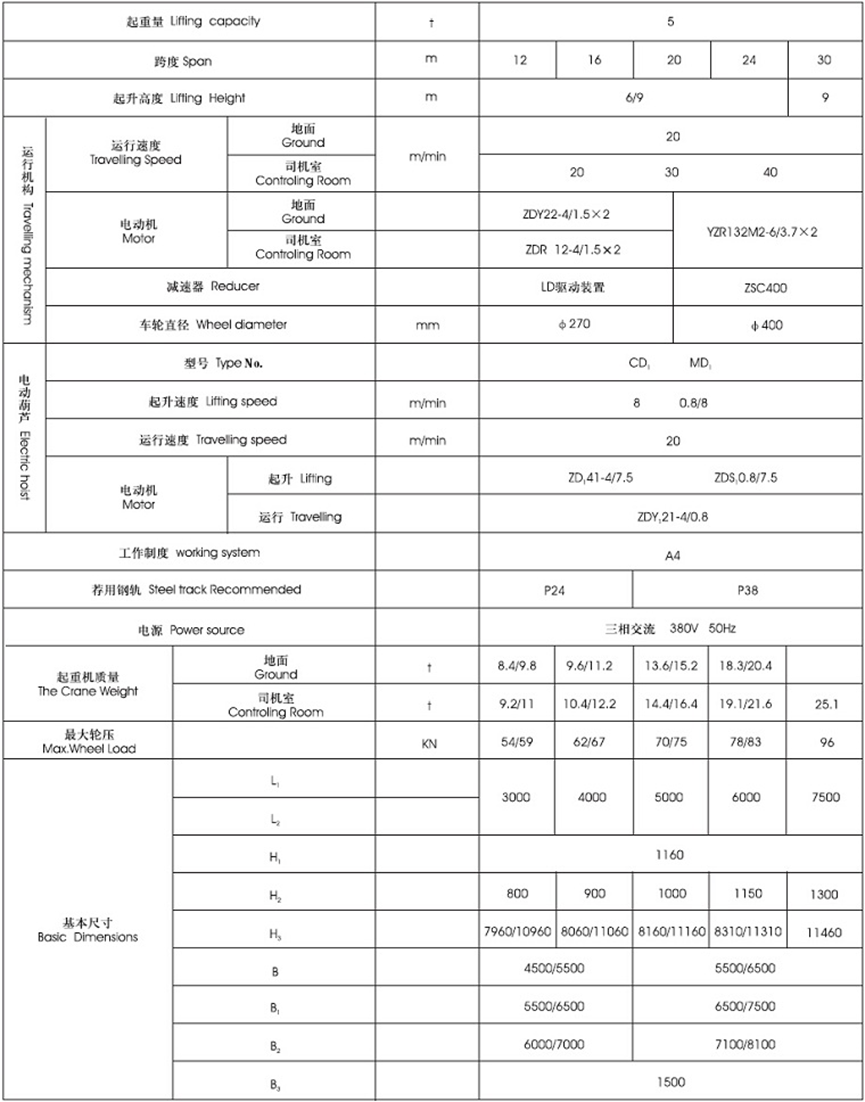

Crane technical parameter is an indicator of the operational capability of the crane, its main parameters including: lifting capacity, lifting height, span, working-level, working speed, etc., you can check the general drawing. Various components (such as: reducer, motor, brake, etc.) operation and maintenance, please refer to the manual.

U-type gantry crane is double-girder gantry crane, suitable for open freight yards and along railway operations, because the large leg space, it is suitable for lifting large volumes of goods, and also can lift containers, its gantry frame is similar with container gantry.

U-type Double Girder Gantry Crane with mature technology, it is safe, reliable, easy to operate and running smooth, it is our company's mature product over the years, as the most widely used cranes in China now.

U-type double-girder gantry crane mainly consists of gantry frame steel structure, trolley and crane traveling mechanism, electrical system and other components. Outdoor work crane also installed with rail clamp, rail anchor device, anemometer, corrective devices, etc.

U-type double girder gantry crane uses double-beam and double-track, winch single trolley structure. Crane winch trolley part is including main and auxiliary hoisting mechanism, each using a separate transmission set. Main and auxiliary hoisting mechanism not only can independently complete lifting, but also can be coordinated to complete the work of flipping objects.

![]()

L-type gantry crane is single girder gantry crane; with large net space due to L-shaped structure. With light weight, low overall height; the structure is compact, more cost savings, and it is cost-effective gantry crane with respect to A-type and U-type gantry crane. Maximum lifting capacity is of 50 tons. Widely used in open-air yards, docks, along railway operations and other places.

L type single girder gantry crane mainly consists of the L-shaped bridge frame, traveling mechanism, trolley parts, electrical control system and other components.

Gantry frame steel structure of L-type single girder gantry crane mainly consists of the main beam, L-type legs, lower cross beam (crane traveling parts) and other components. Connection by high strength bolts.

Crane traveling parts included in the lower cross beam, motor drive through reducer, with reasonable structure, smooth operation.

Semi-Gantry Crane is A-type double girder or single girder gantry crane which only have one unilateral leg, one side of it is the leg traveling on the ground track, the other side is the end of the bridge girder institution traveling on the bracket track, it saves cost and space of operation plant and open area.

Semi-Gantry Crane form three-dimensional work space by hook moving up and down, trolley traveling left and right and crane traveling back and forth, to achieve moving, overturning and other operations for lifting goods.

Semi-Gantry Crane mechanical structure is mainly composed of: bridge frame, crane traveling mechanism, trolley part and electrical part. Bridge frame is mainly composed of: main beam, upper cross beam, lower cross beam, unilateral leg, ladder platform and other components.

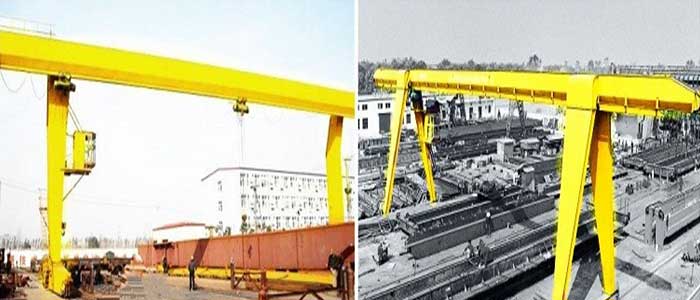

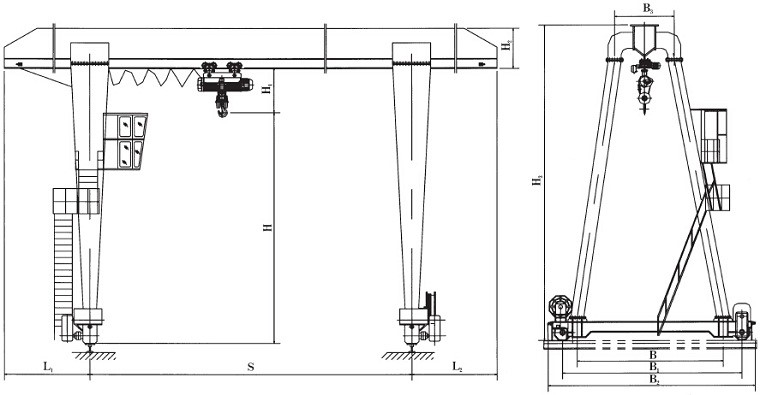

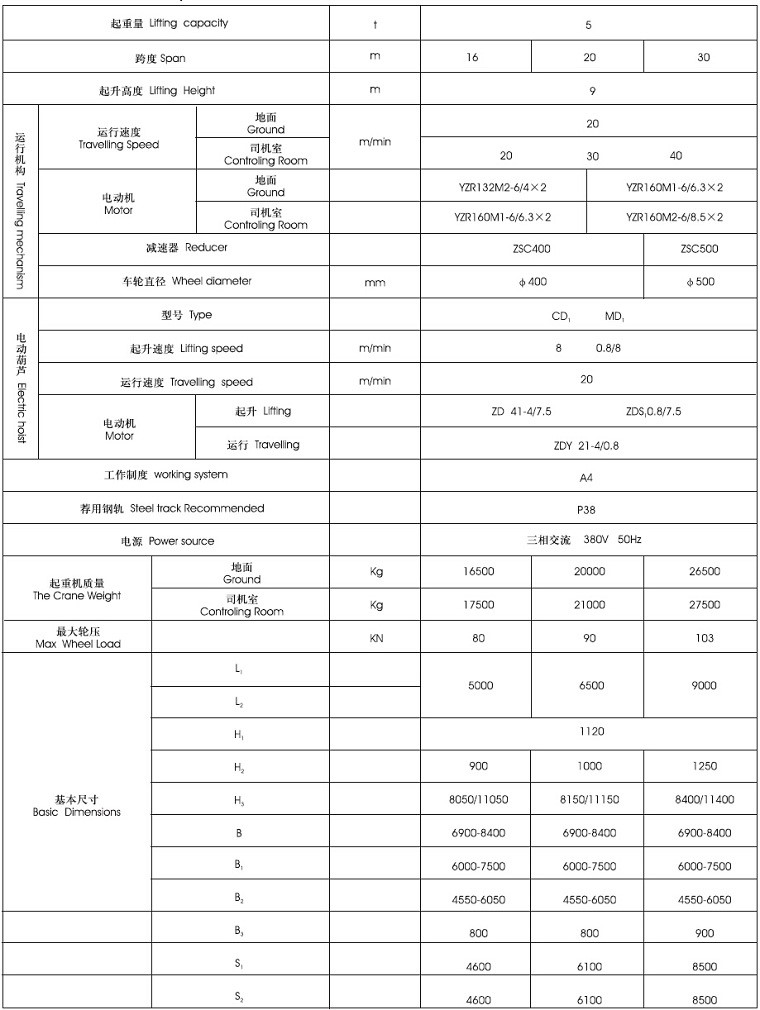

Electric Hoist Gantry Crane is light type gantry crane take CD electric hoist or MD electric hoist as lifting mechanism, through lifting mechanism - electric hoist hook moves up and down, trolley moves left and right and the crane back and forth traveling combined forming the stereo work space, to achieve movement, flip and other operations of the lifting objects.

Hoist gantry crane is single girder gantry crane, can be divided into L-type and A-type hoist gantry crane according to the leg shape. Light weight, simple mechanism, easy to operation, widely used in docks, freight yard, warehouses, construction sites and other conditions.

Hoist gantry crane working-level is A4, generally used for outdoor work, the crane and trolley lifting mechanism both set with rain cover.

Shield Gantry Crane is specialized crane adapt to the engineering construction of subway tunnel and river crossing tunnel, mainly for TBM cutterhead, shield body installation of underground excavation equipment, as well as the transporting of tunnel support tube sheet during construction process. It is with stable performance, high efficiency, and easy maintenance.

Upper spreader of shield gantry crane can swing to accommodate the needs of different directions digging, it is with flexible practices, perfect safety instructions and overload protection device, to protect the equipment and operator’s safety on maximize, electrical systems use of PLC frequency which has conducive to the control of all mechanisms.

Shield gantry crane using rotary spreader, can rotate 360 degrees to accommodate mounting cutter in different angle. Adopt double-trolley structure, the two trolleys linkage; lifting cutter, and can also work separately on lifting objects. Including the following specific characteristics:

1. Shield gantry crane can be used in different diameters and different weight shield cutter and tube sheet installation, divided into four series: correspondence the lifting capacity 400 tons, 200 tons, 130tons, and 100 tons, use cutter diameter of 15 m, 13 m, and 6.3 m.

2. Shield gantry crane using ANSYS analysis software to analyze its structure and to optimize the design, so that it reduce the wheel diameter in the case of the structure to meet the operation requirements, reducing crane overall height, decrease wheel pressure, greatly reduce the cost of construction, while giving users bigger and more rational using space, to meet the user’s requirements on lifting the shield machine in a variety of conditions.

3. Shield gantry crane through frequency control, change of wire rope interactive wrapped and other methods to achieve the lifting speed adjustment, adapt to pipe parts and segment installation work under normal operating conditions.

4. Shield gantry crane adopts PLC control, which control efficiency, reaction speed and maintainability has improved significantly.

5. Shield gantry crane using new type rotatable multi-purpose crane spreader which is of our own proprietary to suit the needs of different digging directions.

6. When the lifting weight is small of shield gantry crane, through changing the pulley rope interactive winding way, wrap the rope around the new pulley block, which change the lifting pulley block magnification, speed up the lifting speed.

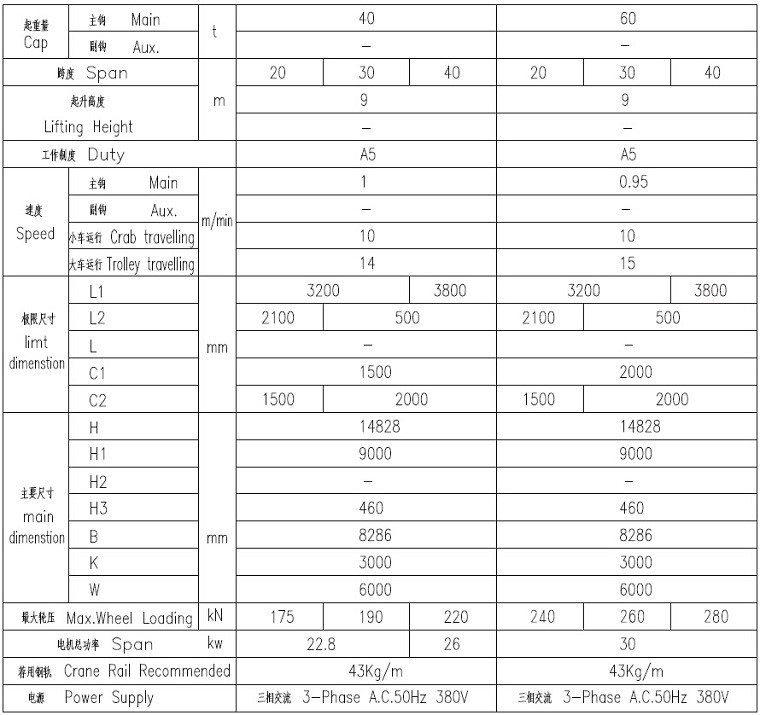

Truss type gantry crane using truss structure, welded from shaped-steel, divided into two working-level mid-level and light-level system according to the busy degree of use. Mainly used in factories, open area between fixed cross, construction and installation sites, lumber yards and other places, due to the wind size is smaller than the box-shaped structure, it is particularly suitable for large sandstorm place, generally for handling and lifting work.

Truss type gantry crane main structure with light weight, small wheel pressure and reliable performance, evolved by Russian gantry crane.

Truss gantry crane is mainly composed of truss girder, legs, lower cross beams and other components, structure components using shaft connecting, easy disassembly and transport. The whole crane adopts single girder, trolley part using hoist or electric hoist, trolley across the upper part of the main beam, hoisting mechanism lifting rope from both sides of the main beam, which can lift shape large object. All mechanisms operating in the driver’s cabin and all set up with rain cover.

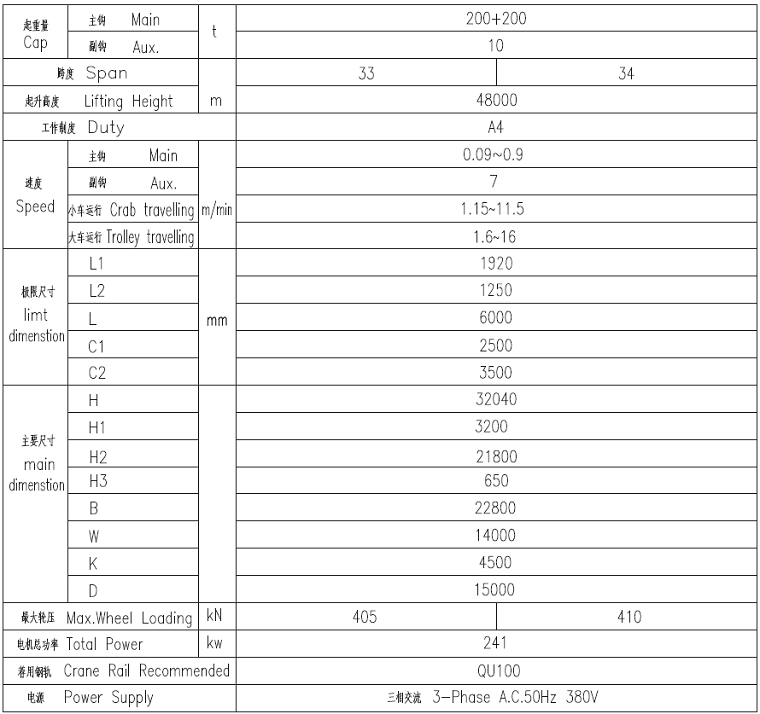

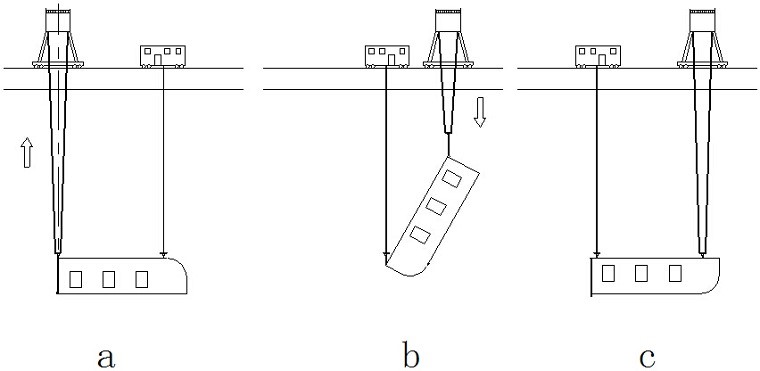

Shipbuilding gantry crane has functions of lifting, handling and segmented turning in the air. The hull turning, close operations and other characteristics are particularly prominent. The crane is double girder, has upper and lower double trolley, segmented turn over operation through the two trolleys. There are four tracks in the main beam for the upper and lower trolley traveling.

Shipbuilding gantry crane mainly consists of gantry frame structure, the upper and lower trolley, crane traveling mechanism, electrical equipment and repair use cantilever slewing crane and other components. Maintenance crane mounted on top of the rigid leg, cabin fixed on the rigid leg. The lower trolley can pass through the bottom of the upper trolley, traveling on each of their own track.

Crane traveling power supply use cable drum. Upper and lower trolley use suspension cable pulley device supply power, they are respectively provided on the top surface of the two main beams.

![]()