Introduction

In industries like construction, manufacturing, and logistics, efficient material handling is critical. Traditional lifting methods often struggle with heavy, bulky loads like steel beams or plates, posing safety risks and inefficiencies. Enter DQCRANES, a leader in innovative crane solutions, with their cutting-edge electromagnetic beam spreaders—a game-changer for lifting magnetic materials. This article explores how DQCRANES’ technology enhances safety, productivity, and cost-effectiveness in industrial settings.

What Are Electromagnetic Beam Spreaders?

The electromagnetic beam spreader is a lifting device for

overhead cranes and

gantry cranes that use controlled electromagnetism to securely lift and distribute heavy ferrous materials. Unlike mechanical clamps or slings, these devices eliminate direct contact with the load, reducing wear and tear while ensuring precise handling.

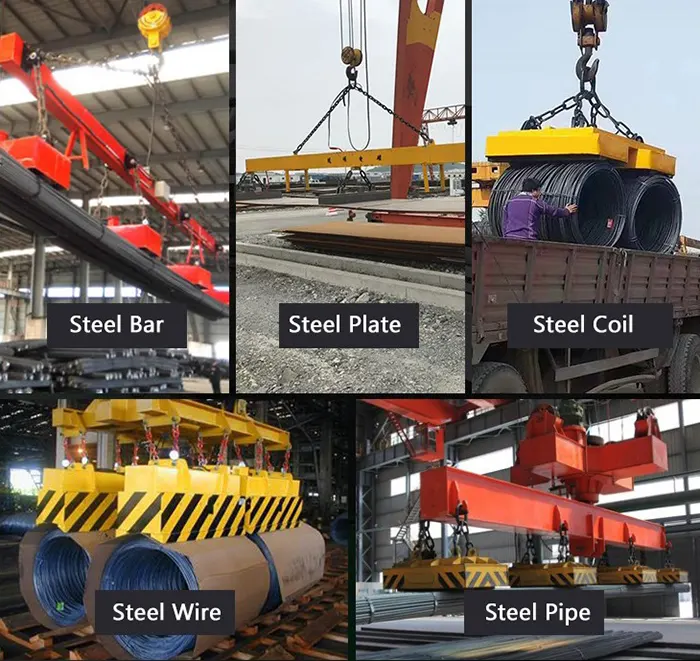

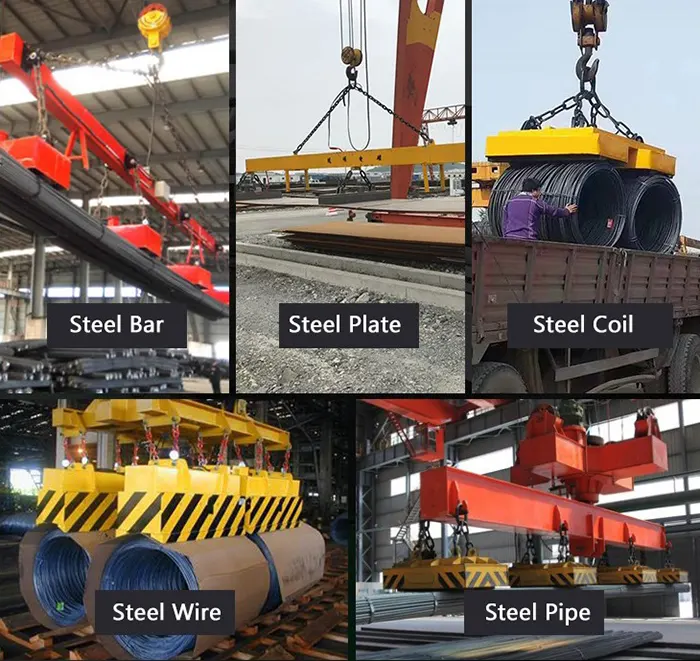

Electromagnetic Lifting Beam Spreader offered by DQCRANES is designed for steel product handling in steel plants and can lift steel pipes, bars, coils, plates, sheets, billets, slabs, etc. Different lifting solutions are customized according to different steel plate profiles, power failure will not lose magnetism, and will not damage workpieces. Multiple electro-permanent magnets can be grouped and controlled, saving time and improving work efficiency.

Design Features

- Electromagnetic Beam Spreader only uses electric power before lifting and the moment before unloading, energy saving. Other times, it does not consume electrical power and does not lose magnetism. It is safe.

- It is equipped with remote controls for easy operation and can be grouped and controlled by permanent magnets. And the magnetic force is adjustable.

- Strong magnetic force without attenuation. Maintenance-free magnetic blocks, no maintenance.

- For cranes, this spreader can be a rotatable, or rotatable hoist trolley with a non-rotatable spreader. Both are available.

- The electromagnet can made in different shapes according to the specific applications, such as square, round, rectangle, etc.

Safety Features

- Fail-Safe Mechanisms: Backup power systems prevent accidental drops.

- Overload Protection: Sensors alert operators to exceeding weight limits.

- Remote Control Operation: Enables safe handling from a distance.

How Do They Work?

- Electromagnetic Activation: When energized, the spreader generates a magnetic field, securely attaching to ferrous materials.

- Adjustable Spread: Operators can adjust the beam width to accommodate different load sizes, ensuring optimal weight distribution.

- Controlled Release: Deactivating the magnetism allows safe, instant release of the load, minimizing downtime.

Key Benefits

Enhanced Safety:

- Eliminates slippage or load shifts with secure magnetic adhesion.

- Reduces manual intervention, lowering injury risks.

Increased Efficiency:

- Faster load attachment/detachment speeds up operations.

- Handles irregularly shaped materials effortlessly.

Cost Savings:

- Durable design reduces maintenance costs vs. traditional methods.

- Improves workflow productivity, cutting labor expenses.

Versatility:

- Compatible with overhead cranes, gantry systems, and robotic handlers.

- Adjustable settings for diverse applications, from steel coils to structural beams.

Applications of Electromagnetic Beam Spreaders

DQCRANES' electromagnetic beam spreaders find applications across a wide range of industries, including:

- Steel Mills: Handling steel plates, billets, coils, and structural steel.

- Shipyards: Lifting and transporting steel plates for shipbuilding.

- Warehouses and Distribution Centers: Efficiently moving and organizing steel products.

- Manufacturing Plants: Handling raw materials and finished goods.

- Ports and Terminals: Loading and unloading steel cargo.

Electromagnetic Beam Spreaders for Sale from DQCRANES

DQCRANES offers a range of electromagnetic beam spreaders designed for diverse industrial applications:

Non-Rotating Electromagnetic Beam Spreaders:

Non-Rotating Electromagnetic Beam Spreaders:

- These are designed for straightforward lifting and moving of ferrous materials.

- The orientation of the spreader remains fixed, either parallel or perpendicular to the crane's main girder.

Rotating Electromagnetic Beam Spreaders:

- These offer increased flexibility, allowing for the rotation of the electromagnetic lifting mechanism.

This rotation can be achieved through:

- Upper Rotating Trolley: The trolley itself rotates, allowing the attached spreader to change orientation.

- Lower Rotating Hanging Beam: The electromagnetic beam itself rotates, providing a more precise control of the load's position.

Automated/Remote-Controlled Spreaders:

- Integrated with automation systems, IoT sensors, or remote controls for precision, safety, and real-time monitoring.

Specialized Application Spreaders:

- Tailored for specific materials (e.g., steel coils, plates, or structural beams) or environments (e.g., high-temperature zones).

Each type may include additional features like fail-safe mechanisms, overload protection, or energy-efficient electromagnet systems. For precise details, consulting DQCRANES’ product specifications or technical support would be recommended.

Why Choose DQCRANES?

- Extensive Experience: Decades of experience in the material handling industry.

- Quality Products: High-performance and reliable equipment built to last.

- Custom Solutions: Tailored designs to meet unique application requirements.

- Global Reach: Serving customers worldwide with prompt and efficient service.

- Competitive Pricing: Offering cost-effective solutions without compromising quality.

By investing in DQCRANES' electromagnetic beam spreaders, you can enhance efficiency, improve safety, and streamline your material handling operations.

Conclusion

DQCRANES’ electromagnetic beam spreaders redefine material handling by merging innovation with reliability. Whether lifting delicate steel coils or massive girders, these devices ensure unmatched safety and efficiency.

Ready to optimize your material handling operations with DQCRANES' electromagnetic beam spreaders?

Contact us today for a consultation and a customized solution tailored to your specific needs.