Various kinds of lifting devices are used with types of lift cranes to perform the material handling tasks. In today’s operational guide of lifting devices, the general procedures on lifting devices installation, inspection, maintenance and repairs, operation, and lifting crane operator training, etc.

Lifting devices also called the below-hook devices are used with various types of lifting equipment, such as, lifte cranes, electric hoists, trolley and other types of lifting cranes and hoists, etc. As one of the lifting crane parts, lifting devices are directly influences the lifting efficiency of the lift cranes. Therefore, the lifting devices operation guide is presented, hoping it is useful.

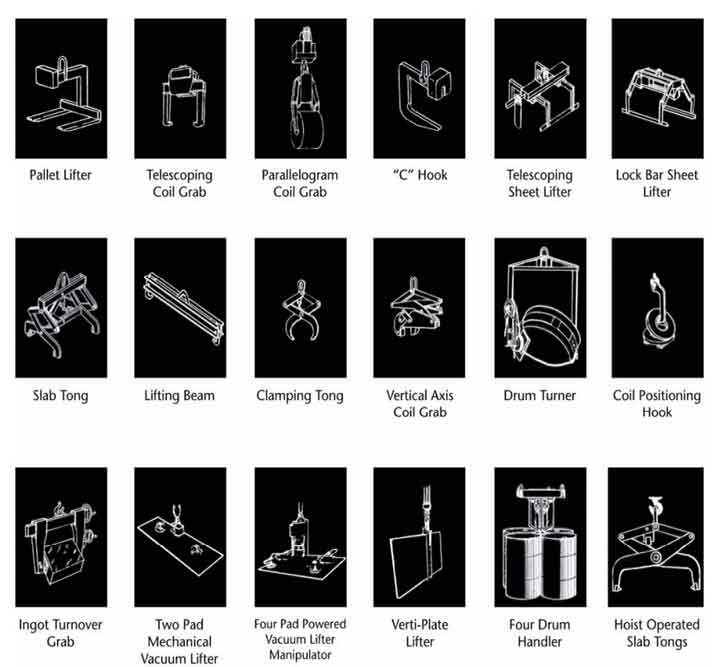

Generally, the below-hook devices can be grouped according to the supporting, indentation type pressure gripping or friction type pressure griping, etc. In the following, different types of lift devices will be presented for your references.

The general operational guide for lifting devices are presented for your references which are used with the instruction manuals of the lifting devices and lifting cranes given by the manufacturers. Any doubts or problems should be solved by consulting the lifting devices manufacturers and lift crane manufacturers or you can leave a message below.

The potential hazards of using lifting devices could not be solved solely be mechanical means which requires the attention, care and common sense of lifting crane operators, and the safety supervisor who has been trained on the lifting devices and lift cranes.

The crane lift devices operational guide can not be the substitute of your crane lift devices manual which is offered as general guide to help in the pursuit of efficient operation of lifting devices.

Design modifications of crane lift devices should be performed according to the full understanding and approval of the manufacturer or it may cause danger and resulting in danger.

The nameplate of crane lift devices should have the following information:

Crane lift devices tags should include the following information:

Note: All warning labels should be maintained visible and legible and replace as necessary.

As one of the lifting crane parts, the lifting devices should be assembled and installed on the lifting cranes according to the instruction.

Attention:

When the crane lifting devices operation needs extra power supply, the power source must be matched with the requirements, which also should be connected with the line side of the lifting crane disconnect switch or an independent circuit as specified in the manufacturer’s operating instructions.

Lifting devices should be inspected before any crane lifting operation and regularly inspections is also needed to reduce crane lifting hazard and risk.

Initial inspection of crane lifting devices

Before operation, all the lifting devices should be inspected by professional inspector according to the instruction of manufacturer’s.

Frequent in service inspection

Depend on the types of crane lifting devices, regular inspection should be conducted daily, weekly or according to the manufacturer’s instruction. During inspection, deficiencies to look for include but not limited to:

1. Crane lifting devices of structural deformation.

2. Cracks or distortion in the structural frame, hoist-hook attachment points, attached slings, cracks in welds, mechanically operation parts, clevises or hooks.

3. Malfunctions during the lifting devices operation.

4. Wear of hoist hook devices, pins, slings, linkages or load supporting clevises or mechanical parts.

Periodic in service inspection

Crane lifting devices should be inspected by professional inspector according to the manufacturer’s instructions monthly and yearly to check whether parts have worn beyond the limits.

Attention:

1. Out of service tag should be tagged on the lifting devices once any deficiencies are detected.

2. Power should be disconnected at source before servicing and follow lock out/tag out procedures to avoid danger of electrocution.

3. The lifting devices should not go on operation until the repairs has been finished.

4. All the inspection and maintenance procedures should be recorded timely.

Maintenance

A preventative maintenance program should be established for each and every crane lifting devices based on manufacturer’s recommendations.

Repairs

Crane lifting devices repairs should be conducted by qualified person. Also all the crane lifting devices repairs and modifications should be performed by or under the direction of the lifting crane manufacturer.

Attention:

1. All the repaired crane lifting devices should be operationally tested. And load test is also needed before being returned to services.

2. All the repairs and parts replacements should be filed on dates.

Crane lifting devices should be operated by professional lifting crane operators, who should be well trained and know well about the lifting crane devices, crane lifting operation, crane lifting safety and others, etc.

Operator training

Crane lifting devices should be operated according to the manufacturer’s operating instructions. Crane lifting operation should be in according to the principles and rules in the manufacturer’s guidelines. Crane lifting safety training should include:

Operating practices