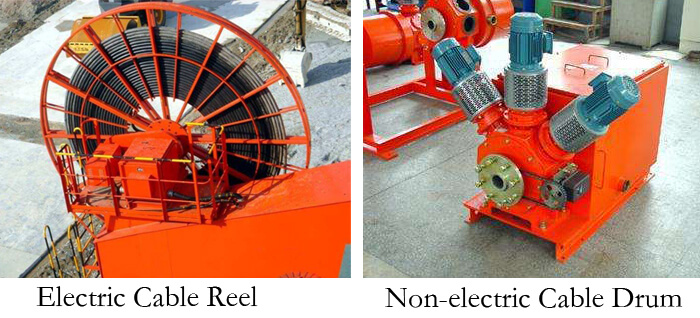

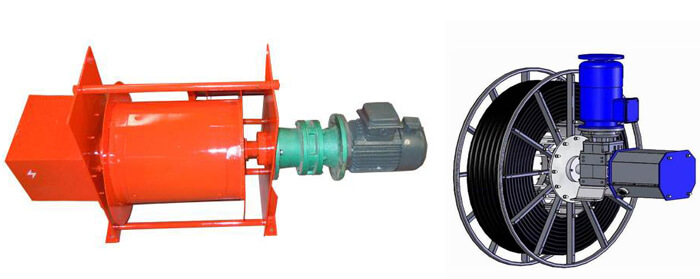

Crane cable drum, also known as crane cable reel, with its small installation space, easy maintenance, the use of reliable and low cost to replace the bus bar and become the mobile transmission field (power, data and fluid media) mainstream solution program.

Cable drum according to the drive form is divided into two types of non-electric and electric; according to the cable arrangement is divided into axial single row and axial row of two; according to the location of the slip ring is divided into slip ring built- Ring outside the two forms; according to the winding material is divided into cable drum and hose drum.

The non-electric type includes: elastic (TA), heavy hammer (ZC), magnetic coupling (JQC); the electric type includes: magnetic coupling type (JQD), torque motor type (KDO), hysteresis type (CZ) and frequency conversion control type (BP).

The working principle of the elastic cable drum is similar to that of the steel tape, and the cable is used to drive the cable with the scroll spring. When the cable is pulled out, tighten the scroll spring and energy storage, when the external force is removed, the spring release, the reel will automatically rewind the cable.

Installation is simple, synchronization performance is good and cable tension is small, but the spring easy fatigue, short life.

Heavy hammer cable reel is the use of heavy hammer was upgraded to the principle of energy storage, automatic coiling cable mechanism. When the cable is pulled out, drive the cable reel to rotate, so as to drive the cable reel coaxial with the wire rope reel rotation, lifting the hammer and storage potential energy. When the reel to be coiled cable, the hammer down the release of potential energy, under the action of wire rope tension, driven by the cable reel coaxial cable reel rotation, synchronous coiling cable.

Simple structure; stable and reliable performance; easy installation and maintenance.

When the equipment is heading for the ground cable, the torque motor is energized and the reel is rotated by the reducer. As the winding diameter increases, the torque motor automatically reduces the speed and increases the output torque to ensure that the linear speed of the cable is synchronized with the speed of the cart and keeps the cable tension constant.

When the equipment is away from the ground cable anchor, the direction of the electromotive force of the torque motor does not change, and the cable is dragged when the cart is running to produce the reverse torque greater than the forward torque of the motor and release the cable synchronously.

Power transfer motor has a long-term stall characteristics, and the cart control system is relatively independent, just from the device total power switch (or total contactor) can lead to power. Electrical control is simple and reliable.

After the cart is powered on, the reel motor is energized and the reel is working, regardless of whether the cart is running, reversing or stopping, the torque motor is always energized and phase sequence is the same; after the car is powered off, the motor is powered off and the reel brake.

By the three-phase asynchronous motor and hysteresis coupling cable drum composed of power speed control system. When the device is heading for the cable anchor, the motor is energized and the reel is driven by the reducer to drive the reel. In this process, the hysteresis driver is used to adjust the speed difference to ensure that the cable is synchronized with the running of the cart. When the equipment is away from the cable anchor, the motor is energized and the phase is the same. When the cart is running, drag the cable to make the reel Greater than the magnetic torque of the hysteresis driver, the cable is released synchronously.

The hysteresis cable reel is a constant torque output. The motor must be started synchronously with the host travel mechanism. When the main unit stops, the drum can be switched off according to the taxiing condition. If you use multiple hysteresis drives, you must ensure that the motor turns consistent and meets the order requirements. That is: the cart travel, reel motor power, whether car or car, reel motor phase sequence unchanged; cart stop, reel motor delay power.

Dongqi Group can provide you electric crane cable reel and non-electric crane cable drum, if you need please contact us freely.