Existing in the design of crane, the habit of calculating bridge machine big wheel pressure method is in accordance with the maximum load and at bridge machine trolley lifting limit position calculation, the calculation method is conservative and in fact most of the bridge machine in lifting the maximum rated load when the trolley doesn't run to the limit position.

The most obvious example is hydropower station is used for lifting turbine bridge machine, since the installation position of water turbine are often near the centerline of the workshop, so the car don't need to also cannot be despatched to the far away from the central axis of the limit position, such as according to the great wheel of the car is in a limit position calculated pressure is actually much higher than the real wheel pressure, according to the design of the wheel pressure workshop will be because of the rich strength too much waste.

In a power station as an example, estimate the pressure great wheel crane, every 10% increase of the crane beam, pillar and foundation of the cost will be increased by 5% ~ 7%. If considering the actual wheel pressure less than 100 kN, wheel load is about 1 million yuan can save the cost of a plant.

The above example is given to illustrate the actual wheel is not used to calculate the pressure so big, that is used to design, according to the existing crane design will greatly overestimate the cart wheel pressure, thus increasing plant cost, cause unnecessary waste.

Factors should be considered for calculating the wheel pressure of overhead crane

If the maximum load of the lifting, should the position of the practical need of according to the trolley. generally, when the largest crane load, the car used in the central part of the main girder nearby, at this time of the cart wheel pressure than the cars in the main girder end is much smaller.

If the trolley run to the main girder end, it should be calculated according to actual loading quantity at this time. generally, when the car running to the main girder end, usually without lifting the maximum load, the cart wheel pressure than the maximum load when lifting is much smaller.

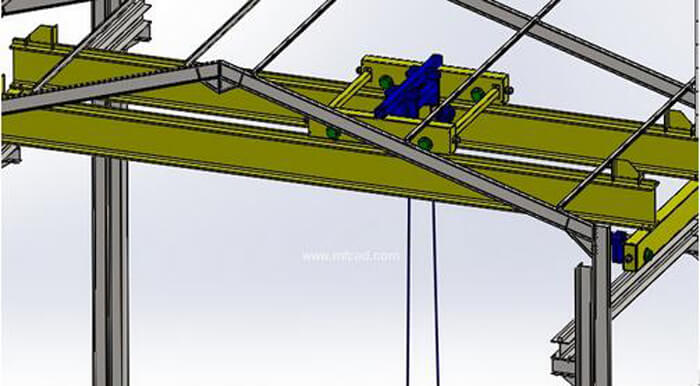

Here to recommend a kind of the lifting weight chain control strategy with the location of the crane trolley, to control the operation of the trolley position by PIE, make it no more than when the load is allowed to reach position.Installed in the trolley on the lifting mechanism of load sensors, used to measure and calculate the current weight 9;Position sensor installed on the trolley running mechanism, is used to measure the position of the trolley on the main girder.Load sensor signal transmission to the PIE, PIE to calculate the weight, at this time and through the calculation (or by looking up has good form) was determined under the lifting weight allows the trolley to reach the farthest location Sd (this position at the end of lifting weight more hours more close to the main girder, the closer when lifting weight, the greater the girder center), and with the position sensor of the trolley. The current positions compare, if s < Sd is not permitted, the current position can run normally, if the current position is close to a value and is near to the permissible value, the PIE start braking process, by controlling the motor and brake, make the position of the trolley does not exceed allowable values, and at the same time issued a warning to the driver information.

PIE has high reliability, and design of computer is designed for industrial control site, adopted many anti-jamming, automatic protection, and improve the reliability of the measures, such as shielding, isolation, filtering, Wateh - dog circuit, the zero correction, nonlinearity control, since the diagnostic circuit, etc., in the aspect of software also can take a lot of ways.Now PIE trouble-free working time has reached more than 3 o m h, numerous practical application has proved that the reliability of the PIE with allows users to rest assured completely.

Sensor is a key link, is also the most vulnerable link, price is not expensive but the sensor itself, in order to ensure the reliability of redundant precautions should be, namely using two or more sensors to measure the same quantities, PLC will use one partial conservative measurements used in the calculation.Lifting weight measurement and limit load sensor, weighing instrument can be used to complete, the trolley position measuring absolute encoder can be used to complete.

Currently used three-phase asynchronous motor, the crane can be used with mechanical brake, also can increase the reverse connect braking function, in the car close to set limits to brake position.

Although the above recommended wheel pressure calculation method is reasonable, according to this calculation, in many cases, the workshop of the crane beam, pillar and foundation of cost will be greatly reduced, economic benefit is very significant (crane PLC control system to increase the costs of general of the cost of factory building of the savings by l %).But the real but almost no one in the actual product design using this algorithm, the main reason is the user and part of the design of this algorithm is not assured, by his grasp of the limitations of technology, that may not be safe enough.This is a misunderstanding.Ensure the security of the system should not be based on the algorithm error, but should be based on correct algorithm and take the right measures such as increasing safety factor, limit and alarm measures, etc.).And this method is not entirely without precedent, in fact on the construction of tower crane and crane, over the years has been using torque limiter for lifting weight and working range and scale length of hoist boom of comprehensive control, to ensure that the crane will not tilting.These security restrictions and the PLC control system, there is no essential difference between above.

To sum up, in the past for bridge crane wheel pressure calculation method of imperfect, poor accuracy, lead to calculate the crane wheel pressure slants big, plant design is too conservative and caused great waste, at present the majority of users may be difficult to find the value in it.There may be many users and designers in order to improve the security of the so-called and used the algorithm used in the parts manual, but the author thinks that enhance security should not be based on the error of algorithm, and should be based on the correct algorithm and the use of advanced technology and the right measures to complete, such as increasing safety coefficient, limit and alarm measures, etc.).Such not only can reduce the crane wheel pressure, biggest and workshops can greatly save cost.