DQCRANES, a leading material handling solutions provider, recently worked with a client in Dominica who required

jib cranes for their assembly lines. After contacting DQCRANES for assistance, the client was presented with tailored solutions in the form of 1 set of 0.5 ton

pillar jib crane and 2 sets of 1 ton

wall mounted jib cranes.

Requirements

The client, a reputable manufacturer in Dominica, specializes in producing a wide range of products for various industries. With a focus on quality and efficiency, the client sought to enhance their assembly lines with the latest material handling equipment. Understanding the importance of reliable lifting solutions in their operations, the client reached out to DQCRANES for expert guidance and support.

Upon engaging with the client, it became evident that their specific requirements revolved around the need for jib cranes that could be seamlessly integrated into their assembly lines. The client emphasized the importance of precision, safety, and durability in the design and functionality of the jib cranes. Additionally, they required a solution that would optimize their workflow and contribute to overall productivity.

Jib Crane Solutions

Receiving the inquiry, DQCRANES promptly assigned a dedicated team of engineers and specialists to assess the client's needs and propose tailored solutions that would address their specific challenges. After conducting a thorough analysis of the client's assembly lines and production processes, DQCRANES recommended the implementation of both pillar jib crane and wall mounted jib cranes to effectively meet the lifting requirements. The 500kg pillar mounted jib crane was proposed for areas where a dedicated vertical support structure was feasible, while the 1 ton wall mounted crane was suggested for locations with limited floor space.

Reminder: Customers need to equip their own lifting mechanism, so they require us to design it according to manual rotation and do not need to provide electric hoists.

Reminder: Customers need to equip their own lifting mechanism, so they require us to design it according to manual rotation and do not need to provide electric hoists.

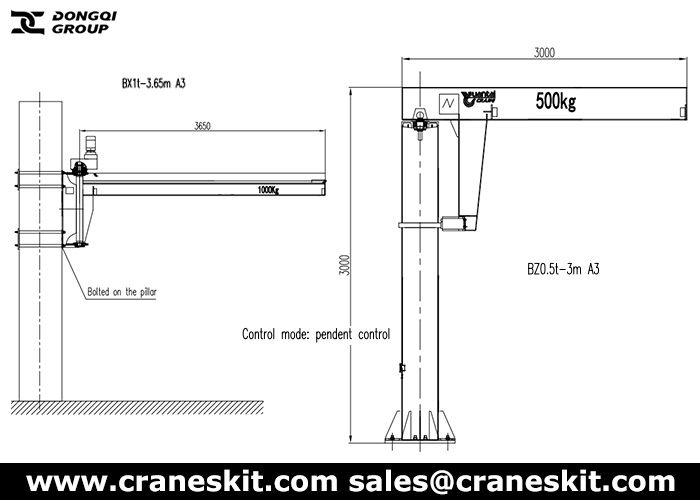

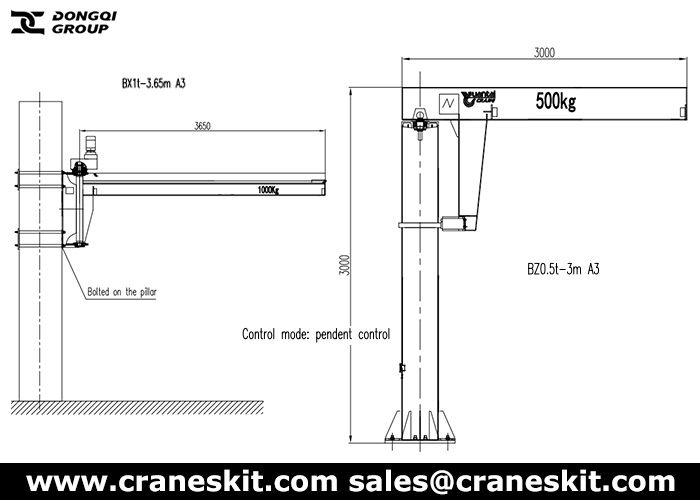

500kg Pillar Mounted Jib Crane

Design Details:

Design Details:The 500kg pillar mount jib crane is designed to handle loads up to 500kg within a specific radius. The

jib crane for sale consists of a vertical column that is securely anchored to the floor, providing stability and support for the jib arm. The jib arm is then attached to the top of the column and can rotate a full 360 degrees by manpower, allowing for maximum coverage within the designated work area.

Design Features:

- The jib arm is typically made of high-strength steel to ensure durability and longevity.

- The client's existing lifting device is attached to the end of the jib arm, providing the capability to lift and move heavy loads with precision.

- The column mounted design allows for easy installation and minimal impact on existing floor space.

- Some models may feature a motorized rotation system (Optional), allowing for effortless movement of the jib arm and load.

| Crane type |

Pillar Jib Crane |

Wall Mounted Jib Crane |

| Model |

BZ |

BX |

| Working class |

A3 |

A3 |

| Lifting capacity |

500KG |

1000KG |

| Arm length |

3m |

3.65m |

| Lifting height |

3m |

2m |

| Control method |

Pendent control |

Pendent control |

| Power supply |

480V/60Hz/3Phase |

480V/60Hz/3Phase |

| Color |

Yellow |

Yellow |

| Application |

Assembly lines Indoor |

Assembly lines Indoor |

| Quantity |

1 |

2 |

1 Ton Wall Mounted Jib Crane

Design Details:

Design Details:The 1 ton wall mounted jib crane is designed to handle heavier loads, typically up to 1 ton, and is mounted directly to an existing wall or building structure. This type of jib crane is ideal for applications where floor space is limited or where a freestanding column may not be feasible.

Design Features:

- The jib arm is attached to a specially designed bracket that is securely fastened to the wall, providing stability and support for heavy loads.

- Similar to the column mounted jib crane, the jib arm can rotate 120 degrees (Customized), providing a large coverage within the work area.

- The wall mounted design allows for efficient use of space and can be installed at varying heights to accommodate specific assembly line requirements.

- Some models may feature a telescoping jib arm (Optional), providing additional reach and flexibility for handling loads in different locations.

Client's Feedback

Upon reviewing the proposed jib crane solutions, the client expressed satisfaction with the comprehensive approach taken by DQCRANES in addressing their specific needs. The client appreciated the attention to detail in the design and the seamless integration of the jib cranes into their assembly lines. The reliability and performance capabilities of the proposed solutions resonated positively with the client's objectives.

Signed the Contract

Following extensive discussions and consultations, the client proceeded to formalize the partnership by signing a contract with DQCRANES for the supply and installation of the column mounted and wall mounted jib cranes. The terms of the contract outlined the delivery schedule, installation process, and ongoing support from DQCRANES to ensure the successful deployment of the material handling equipment.

Production and Delivery

With the contract in place, DQCRANES commenced the production of the customized jib cranes according to the agreed specifications. The manufacturing process adhered to stringent quality standards, leveraging advanced technologies and skilled craftsmanship to fabricate jib cranes that met the client's exact requirements. Upon completion, the 3 sets of jib cranes were carefully packaged and prepared for shipment to Dominica.

Installation

As part of their end-to-end service commitment, DQCRANES dispatched a team of experienced technicians to oversee the installation of the column mounted and wall mounted jib cranes at the client's facility in Dominica. The installation process was meticulously executed, ensuring seamless integration with the existing assembly lines and compliance with safety regulations. Through close collaboration with the client's operations team, DQCRANES ensured that the jib cranes were fully operational and optimized for performance.

Result

The successful collaboration between DQCRANES and the client in Dominica exemplifies the value of tailored material handling solutions in enhancing manufacturing processes. By leveraging their expertise in designing and delivering jib cranes, DQCRANES effectively addressed the client's specific lifting requirements while contributing to operational efficiency and safety.

Contact DQCRANES to learn about which type of jib crane is most suitable for you!