Introduction

DQCRANES, a renowned name in crane manufacturing, has recently exported four sets of

overhead cranes to casting and forging machinery workshops in America. 2 sets of 10 ton

Double Girder Overhead Cranes and 2 sets of 5 ton

single girder overhead cranes, both are European standards design, ensuring to meet the highest benchmarks of safety, durability, and operational efficiency.

Client's Challenges

The casting and forging sector is integral to producing components essential for various industries, including automotive, aerospace, and heavy machinery. This particular machinery workshop in America faced challenges typical of many manufacturing facilities: the need for increased load capacity, precision handling, and enhanced safety standards. With a growing demand for their products, the workshop required a solution that could seamlessly integrate into their existing operations while providing room for future scalability.

Overhead Crane Design Solution - DQCRANES

With decades of experience in crane manufacturing and a commitment to innovation, DQCRANES has emerged as a trusted partner for industries worldwide. DQCRANES' engineering team worked closely with American clients to understand their operational requirements and constraints. This collaboration ensured that the cranes were not only fit for purpose but also optimized for the specific workflows and spatial configurations of the workshops.

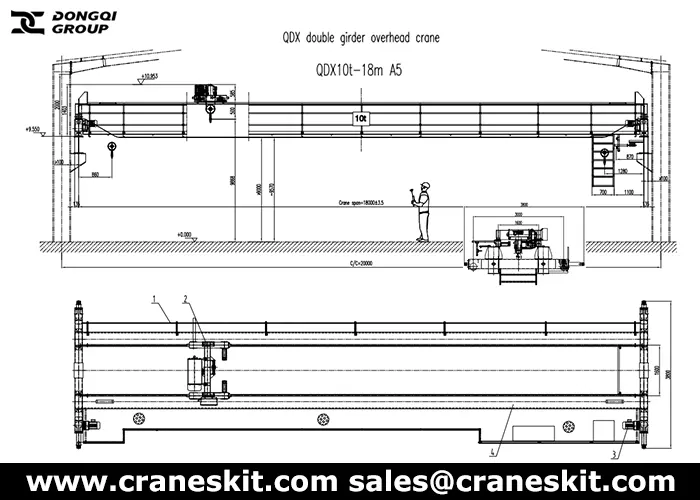

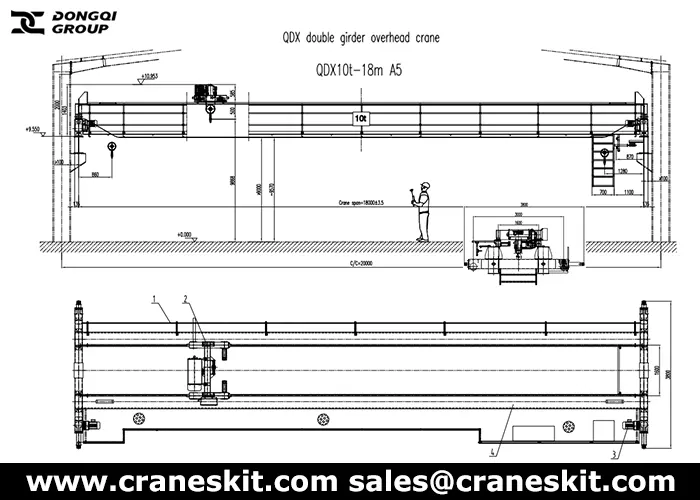

10 Ton Overhead Crane

The 10-ton double girder overhead cranes were designed to handle larger loads with ease. Featuring robust construction and advanced control systems, these cranes offer superior stability and precision in material handling. The double girder design provides enhanced load capacity and span, making it ideal for demanding industrial environments.

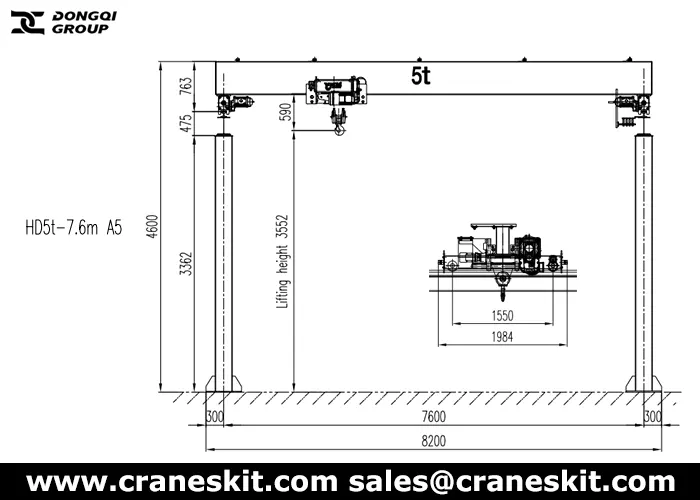

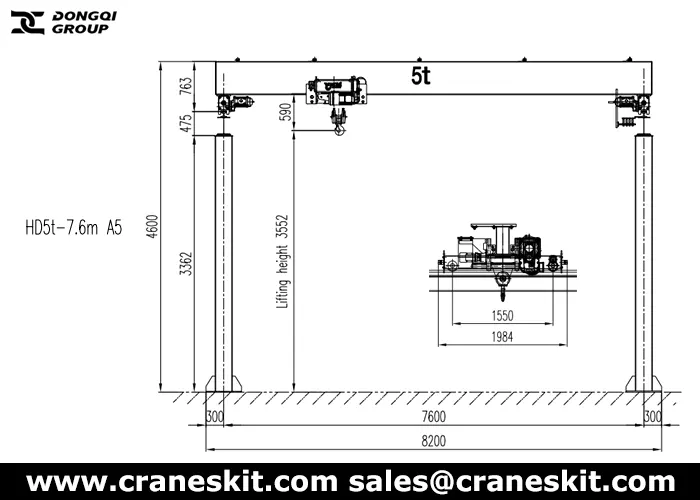

5 ton overhead crane

Conversely, the 5-ton single girder overhead cranes were engineered for applications requiring agility and speed. Their streamlined design allows for efficient operation in tighter spaces while maintaining high standards of safety and reliability. The single girder configuration is particularly advantageous for workshops where space optimization is critical.

European Standards DesignThe

overhead crane for sale to America with European standard design incorporated features such as advanced load monitoring systems, automated safety checks, and energy-efficient motors. These elements contribute to reduced operational costs, enhanced operator safety, and a lower environmental footprint—a trifecta of benefits that resonate well with modern industrial practices.

| Crane |

QDX FEM Standard double girder eot crane |

HD FEM Standard Single Girder EOT Crane |

| Lifting capacity |

10 ton |

5 ton |

| Span |

18m |

7.6m |

| Lifting height |

9.87m |

3.55m |

| Lifting speed |

0.8~5.0m/min STEPLESS |

0.8~5.0m/min STEPLESS |

| Traveling speed |

2.0~20m/min STEPLESS |

2.0~20m/min STEPLESS |

| Working duty |

FEM 2m (A5) |

FEM 2m (A5) |

| Power supply |

380V, 50Hz, 3-phase |

380V, 50Hz, 3-phase |

| Control mode |

Pendent control & Remote control |

Pendent control |

| Working site |

Indoors |

Indoors |

Why Choose European Standard Overhead Cranes?

At DQCRANES, European standard overhead cranes are renowned for their superior design, advanced technology, and stringent safety features. These cranes are engineered to provide enhanced performance and durability, making them ideal for demanding industrial environments.

- Enhanced Safety: With advanced safety features such as overload protection, emergency stop functions, and anti-sway technology, these cranes minimize the risk of accidents and ensure a secure working environment.

- Precision Handling: Equipped with state-of-the-art control systems, these cranes allow for precise maneuvering of materials, which is essential in casting and forging processes where accuracy is critical.

- Increased Efficiency: The ergonomic design and efficient operation of these cranes contribute to reduced downtime and increased productivity, allowing the workshop to meet its production goals effectively.

- Durability and Reliability: Constructed with high-quality materials and components, European standard cranes are built to withstand the rigors of continuous use, ensuring long-term reliability and reduced maintenance costs.

Impact

The introduction of these European standard overhead cranes has had a transformative impact on the American casting and forging workshop. Not only has productivity increased due to improved handling capabilities, but the enhanced safety features have also fostered a safer working environment. The energy-efficient design of the cranes has contributed to reduced operational costs, aligning with the workshop's sustainability goals.

Moreover, by adopting cutting-edge technology from DQCRANES, the workshop has positioned itself as a leader in innovation within its industry. This strategic upgrade not only meets current demands but also sets a solid foundation for future growth and expansion.

Complete Delivery Process

The delivery of these overhead cranes was a meticulously planned operation, reflecting DQCRANES' commitment to excellence. From initial consultation to final installation, every step was executed with precision:

- Consultation and Customization: Understanding the specific needs of the workshop was the first step. DQCRANES' team of experts worked closely with the client to customize the crane specifications, ensuring they met the exact requirements of the workshop's operations.

- Manufacturing Excellence: The cranes were manufactured adhering to the highest quality standards, incorporating cutting-edge technology to enhance performance and safety.

- Logistics and Installation: The logistics team ensured timely delivery of the cranes to the workshop site. A team of skilled technicians then undertook the installation process, ensuring that each crane was set up for optimal performance.

- Training and Support: To ensure seamless integration into the workshop's operations, DQCRANES provided comprehensive training for the workshop staff. This included operational training as well as maintenance procedures to maximize the lifespan and efficiency of the cranes.

Feedback: Exceeding Expectations

Feedback from the workshop has been overwhelmingly positive. The new overhead cranes have significantly improved workflow efficiency, allowing for faster and safer handling of heavy loads. The operators have praised the intuitive controls and robust safety features, which have contributed to a safer working environment.

The workshop management expressed their satisfaction with the entire process, from initial consultation to final installation. They noted that DQCRANES' commitment to quality and customer service was evident at every stage.

DQCRANES: Your Reliable Partner in Material Handling

For businesses seeking to enhance their operational capabilities with cutting-edge crane technology, DQCRANES offers unparalleled expertise and service. Whether you need a custom design or are looking for competitive pricing on standard models, our team is ready to assist.

Contact DQCRANES today to learn more about how we can help you achieve your industrial goals with our advanced overhead crane solutions. Our commitment to excellence ensures that you receive not only a product but a partnership dedicated to your success.