In recent years, the demand for

jib cranes among engineering contractors in

Bangladesh has been on the rise. These contractors often require efficient material handling solutions to streamline their operations and improve productivity. As a leading provider of lifting equipment, DQCRANES understands the unique needs of engineering contractors and offers custom jib crane solutions to meet their specific requirements.

Background

One such engineering contractor in Bangladesh, with a focus on construction and infrastructure development, recently approached DQCRANES with a need for a reliable and robust jib crane to support their ongoing projects. With a reputation for delivering high-quality engineering solutions, the client sought a trusted partner who could provide a tailored lifting solution to enhance their material handling capabilities.

Requirements

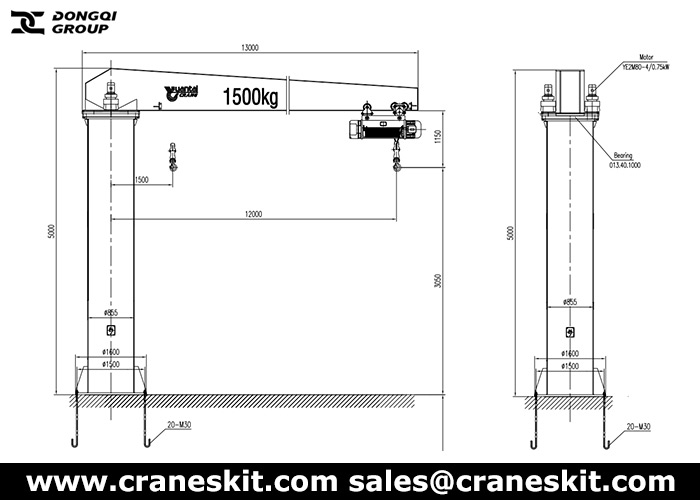

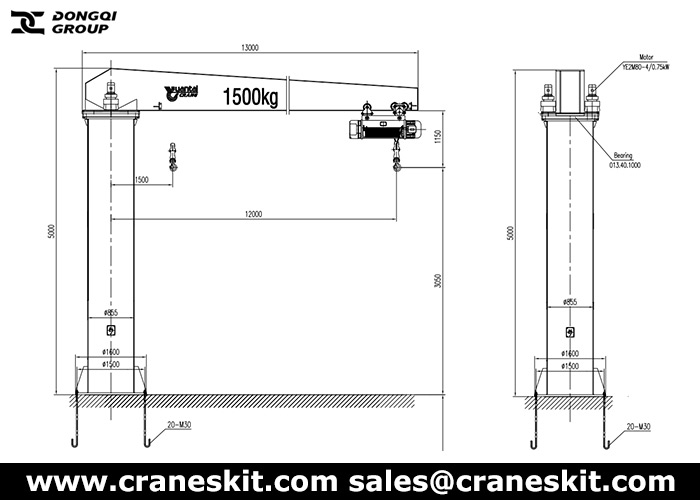

- The client specified several key requirements for the pillar mounted jib crane they were seeking:

- They needed a floor mounted crane with a lifting capacity of 1.5 tons to handle heavy loads commonly encountered at their construction sites.

- Additionally, the jib crane needed to have a long arm length of 12 meters to provide sufficient coverage across their work areas.

- Safety and durability were also top priorities for the client, as they aimed to ensure the well-being of their workers and minimize downtime due to equipment maintenance.

In response to the client's needs, DQCRANES proposed a custom-designed 1.5 ton pillar mounted jib crane with a 12m valid radius (total arm length 13m) that would not only meet but exceed the client's expectations. The design solution incorporated advanced engineering principles and state-of-the-art components to deliver a reliable and efficient lifting solution tailored to the client's specific requirements.

- 360-Degree Rotation: The pillar jib crane offers full-circle rotation, allowing for maximum coverage of the working area without the need for repositioning.

- Precise Positioning: The wire rope hoist and trolley system enable accurate positioning of loads, making it suitable for tasks that require precision and control.

- Space-Saving Design: By utilizing vertical space and minimal floor space, the floor mounted jib crane is an efficient solution for facilities with limited room for maneuvering.

- Customization Options: Pillar mounted jib cranes can be customized to meet specific lifting requirements, including varying load capacities and outreach dimensions.

- Easy Installation: The freestanding design of the pillar jib crane makes it relatively easy to install without the need for extensive modifications to existing structures.

- Low Maintenance: With proper care and regular inspections, pillar jib cranes with wire rope hoists are known for their low maintenance requirements, ensuring minimal downtime and long-term reliability.

Production and Delivery

Following the approval of the custom jib crane design, DQCRANES commenced the production process, leveraging advanced manufacturing facilities and stringent quality control measures to ensure the crane met the highest standards. The production timeline was meticulously managed to deliver the crane within the agreed-upon timeframe, allowing the client to integrate the new lifting solution into their ongoing projects without delay.

Now the pillar jib crane has been delivered to Bangladesh, waiting for installation at the client's site by the local team. DQCRANES eagerly awaited feedback from the engineering contractor in Bangladesh.

Types of Jib Cranes for Sale to Bangladesh

DQCRANES offers a range of jib cranes designed to meet various lifting needs for clients in Bangladesh. Here are some of the types of jib cranes that we have available for sale:

Wall-mounted jib cranes are fixed to the wall or building structure, making them ideal for applications where floor space is limited. These cranes can rotate 180 or 360 degrees, providing easy access to different areas within the workspace. They are suitable for light to medium-duty lifting requirements and offer a cost-effective solution for material handling.

- Pillar-Mounted Jib Cranes:

Pillar-mounted jib cranes are freestanding and are mounted to a concrete foundation, offering stability and support for heavier lifting tasks. These cranes can also rotate 180 or 360 degrees, providing versatility in maneuvering loads within the designated area. They are suitable for medium to heavy-duty lifting requirements and are commonly used in manufacturing facilities, warehouses, and construction sites.

Articulating jib cranes, also known as knuckle jib cranes, feature a second arm that articulates or bends, allowing for greater flexibility in reaching loads around obstacles or obstructions. These cranes are ideal for applications where precision and maneuverability are crucial, such as assembly lines, machining centers, and maintenance workshops.

Portable jib cranes are designed for mobility and can be easily transported to different locations within a facility. These cranes are typically mounted on a movable base or cart, allowing for quick and convenient repositioning as needed. They are suitable for light to medium-duty lifting tasks and are commonly used in workshops, loading docks, and assembly areas.

At DQCRANES, we are committed to providing high-quality jib cranes that are designed to enhance productivity and safety in your operations. Our team of experts can help you select the right jib crane for your application and provide professional installation and maintenance services to ensure optimal performance.

If you're in the market for jib cranes in Bangladesh, please

contact us to learn more about our products and how they can benefit your material handling operations.