Grab bucket

gantry crane is usually used to handle bulk materials such as coal, stone, sand, metal scrap, garbage, etc. It is mainly composed of a gantry structure, trolley, lifting mechanism, electronic control, and grab bucket. The driver's cabin can be equipped which will also travel with the trolley. This type of grab bucket crane is widely used to load and unload materials and loads in mines, ports, factories, workshops, warehouses, goods yards, etc.

Background

Our client is a leading scrap metal recycling company based in Thailand. With a focus on sustainability and environmental responsibility, they are constantly looking for innovative solutions to improve their operations and maximize efficiency. As part of their expansion plans, they approached us - DQCRANES with a requirement for a reliable and high-performance crane with grab bucket to handle the heavy-duty lifting of scrap metal in their yard.

Requirements

The client needed a gantry crane specifically designed to handle the challenging environment of a scrap yard:

- The lifting capacity is 10 ton, equipped with a grab bucket to efficiently load, unload, and transport scrap metal within the yard.

- The gantry crane needed to meet European standards for quality, safety, and performance, and also be suitable for outdoor use in varying weather conditions.

Solution

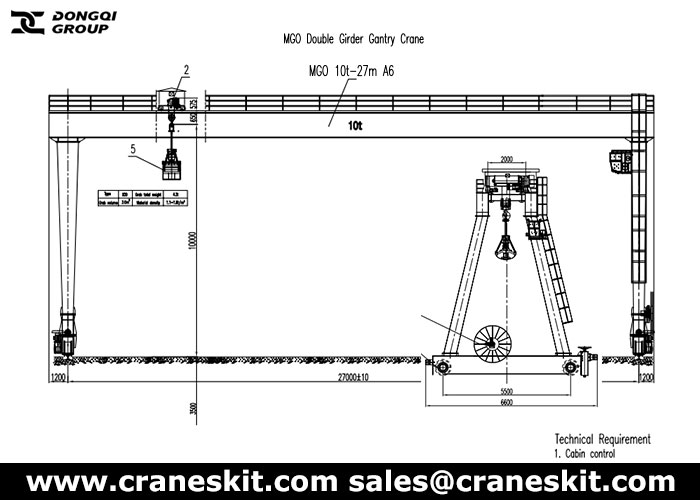

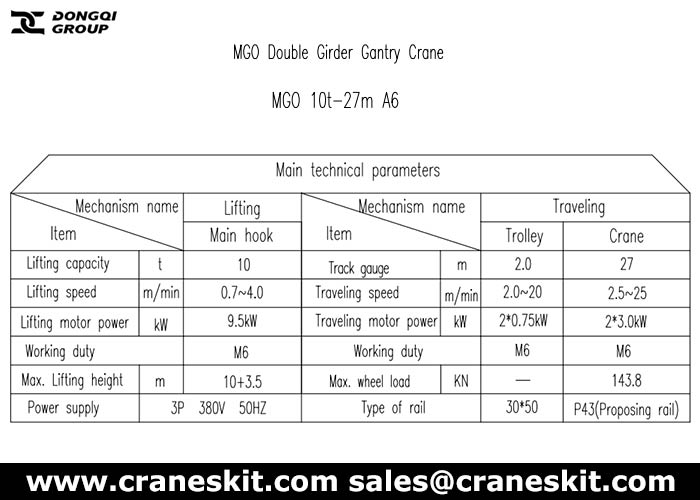

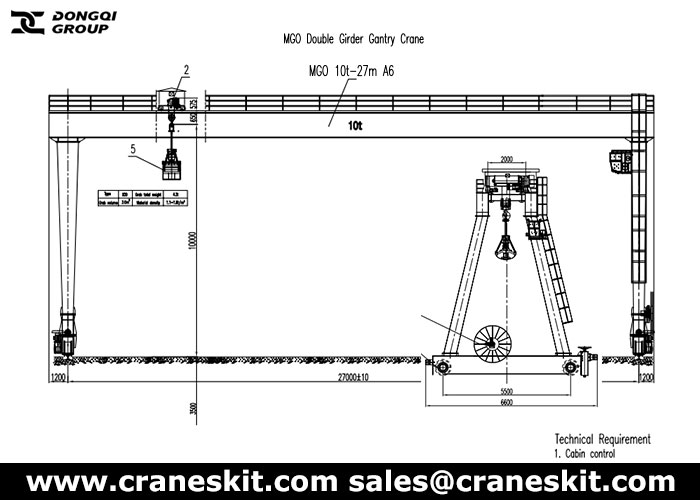

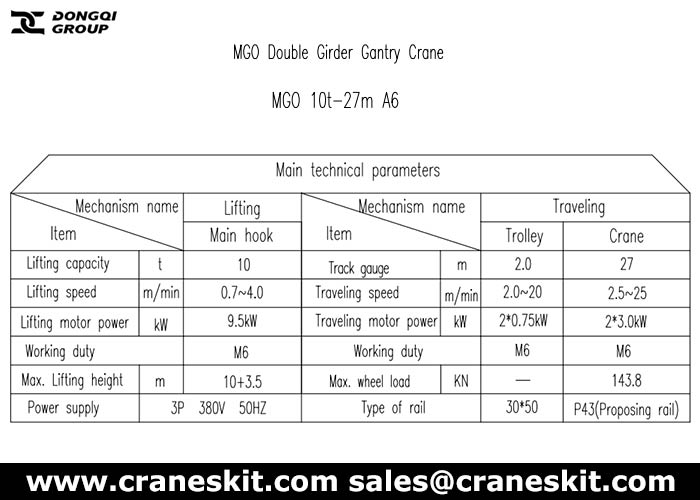

After carefully assessing the client's requirements and the specific challenges of their scrap yard, our team at DQCRANES proposed a tailored solution. We recommended a European standard 10 ton

Double Girder Gantry Crane with grab bucket, designed to withstand the harsh operating conditions of the scrap yard.

The 10t gantry crane was designed with a sturdy double girder configuration to ensure stability and strength for handling heavy loads. The grab bucket attachment was chosen for its ability to efficiently grip and lift irregularly shaped scrap metal, enhancing the crane's versatility and productivity.

To meet European standards, the grab bucket crane was equipped with high-quality components, including hoists, motors, and electrical systems, ensuring reliable performance and long-term durability. Safety features such as overload protection, emergency stop systems, and anti-sway technology were also integrated to prioritize the well-being of the operators and the integrity of the equipment.

Result

After receiving 70% payment in advance, the production was carried out at our manufacturing facility. Our team of skilled engineers and technicians ensured that every component was fabricated to precise specifications and subjected to rigorous quality control measures. Once completed, the crane was tested under simulated operating conditions to validate its performance and safety features. The delivery process was coordinated with meticulous attention to detail to ensure that the gantry crane reached the client's site in Thailand within the stipulated timeframe.

Types of Gantry Cranes for Sale in Thailand

If you are looking for a gantry crane, it's important to understand the different types available to find the right one for your specific needs.

Contact DQCRANES today, as a leading provider of high-quality crane solutions, we are very glad to help you get a suitable gantry crane at good price.

Single girder gantry cranes are a popular choice for light and moderate lifting applications. They are designed with a single beam that runs along the top of the crane, supported by two legs on either side. These cranes are ideal for handling loads up to 20 tons and are commonly used in warehouses, workshops, and small manufacturing facilities. DQCRANES offers a range of single girder gantry cranes with customizable features to meet specific requirements.

- Double Girder Gantry Crane:

For heavier lifting tasks, double girder gantry cranes are the preferred choice. These cranes feature two beams running along the top of the crane, supported by legs on either side. Double girder gantry cranes offer higher lifting capacities, ranging from 5 tons to over 200 tons, making them suitable for heavy-duty industrial applications. DQCRANES provides a variety of double girder gantry cranes with advanced features such as variable speed control, anti-sway technology, and precise load positioning.

Semi-gantry cranes are designed for operations where one end of the crane is supported by a runway system or building structure, while the other end travels on wheels along the ground. These cranes are versatile and can be used in outdoor storage yards, loading docks, and construction sites. DQCRANES offers semi-gantry cranes with customizable span lengths and lifting capacities to accommodate specific project requirements.

Portable gantry cranes are a flexible solution for temporary lifting and moving tasks. These cranes are lightweight, easy to assemble, and can be transported to different job sites as needed. They are commonly used in maintenance workshops, assembly lines, and outdoor construction projects. DQCRANES provides portable gantry cranes with adjustable heights, spans, and lifting capacities to suit diverse applications.

Rail mounted gantry cranes, also known as RMGs, are used in container terminals and intermodal yards for efficiently handling shipping containers. These cranes run on rails and are capable of stacking containers vertically and moving them between trucks, trains, and storage areas. DQCRANES offers rail mounted gantry cranes with advanced automation and control systems to optimize container handling operations.

In conclusion, there are various types of gantry cranes available for sale in Thailand from DQCRANES, each designed to meet specific lifting and moving requirements. Whether you need a crane for light-duty warehouse operations or heavy-duty industrial tasks, DQCRANES offers a comprehensive range of gantry cranes with customizable features to ensure optimal performance and safety.